Reasonable poultry waste disposal methods and equipment are important to mange poultry waste. As a manure to fertilizer equipment manufacturer, SEEC not only can provide you practical equipment, but also economic and efficient methods to deal with poultry litter. The easiest way to manage poultry waste is making compost or drying. If you have enough budget and space to dispose poultry manure, commercial organic fertilizer production from poultry waste is also a fine choice. All of these methods are suitable for both poultry farm waste disposal and organic fertilizer factory.

What kinds of manure disposal methods can be used to manage poultry waste?

In terms of poultry waste management, composting, drying poultry manure and making commercial organic fertilizer are available. Next, we will introduce them one by one.

Method One—To make nutrient-rich poultry manure waste compost

Poultry manure is a good material for making organic fertilizer. By composting, you can use it as base fertilizer, so as to provide nutrients to plants and soil. On the other hand, pathogens, weed seeds and eggs in waste will be killed by high temperature generating from microorganism activity. With the help of poultry composting equipment, you will get quality compost in 20 to 30 days.

Method Two—Making dried poultry manure with lowest cost

Compared with fresh poultry manure, dried poultry manure has less odor and is convenient for long-term storage. In addition, the drying of poultry manure is easy to operate. You can get dry manure with 13% moisture in few minutes with SEEC manure drying system. In terms of dried manure, you can use it for composting, or sell them to others. Because it is also convenient for transportation.

Method Three—Making marketable organic fertilizer

For large scale poultry litter management, you can deeply process composted poultry manure after composting. According to strict national standard on nutrient elements in commercial organic fertilizer, commercial organic fertilizer has higher fertilizer value. At the same time, it needs much more investment on both budget and space. It includes powdery and granular poultry manure fertilizer production.

Fast fermentation system and efficient composting equipment for you to manage poultry waste

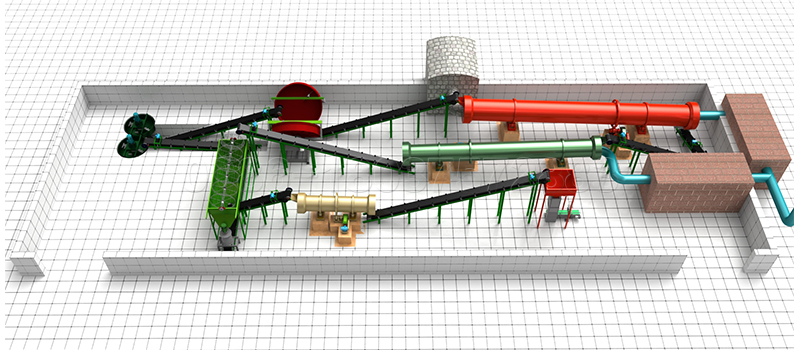

Both windrow composting and fermentation in grooves belong to fast fermentation system. In addition, the important work in fermentation process is to regularly turning the compost pile. For large scale composting, composting equipment is necessary. You can choose suitable composting method and equipment according to actual situations.

Procedures for making compost from poultry manure

Windrow composting and fermentation in grooves are available for composting poultry manure.

- Firstly, you should collect poultry waste, adjust water content to 50% -60%, mix it with some c-rich materials (25:1) (such as straw powder, sawdust and so on).

- Secondly, you can pile them in long rows, which is called windrow composting. The height and width of compost pile usually is more than 0.6 m and 2 m. And the length of compost pile depends on the size of fermentation area. On the other hand, you can build some fermentation grooves to place waste. These grooves usually consist of three walls. For fermentation in grooves, groove type compost turner will be better for you to turn the waste.

- Finally, you start to turn the waste regularly after temperature of compost pile is more than 65 degree centigrade. Composting finishes when poultry manure become loose and black.

Two types efficient composting equipment for greatly shorten composting period

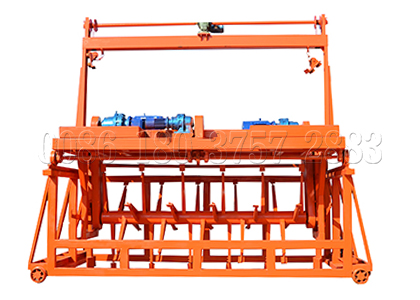

According to composting methods, poultry composting equipment includes windrow compost turner and compost turner for fermentation groove.

- Windrow compost turner: It includes crawler type compost turner and self-propelled compost turner. During working, both of them span over compost pile. At the same time, the turning device which consists of rotary shaft and turning tooth will stir compost pile evenly and crush caking into small pieces. The differences between them are design of wheels and driver’s cab. In addition, one person can operate the windrow compost turner. They use diesel oil as fuel.

- Compost turner used for fermentation grooves: During working, this kind of compost turner works on two paralleled walls. Its turning device evenly stir waste in the fermentation grooves. There is groove type compost turner, wheel type compost turner and chain plate type compost turner for you to choose. You can operate it by control cabinet.

Note: Both windrow compost turner and groove type compost turner can be equipped them with spray device, which can add water to the compost pile during turning.

How to manage poultry waste by making commercial organic fertilizer?

The production of commercial organic fertilizer is after poultry waste composting. Composted poultry waste is just suitable for used as base fertilizer. If you want to sell it in market, you need to add other nutrient elements. You can choose:

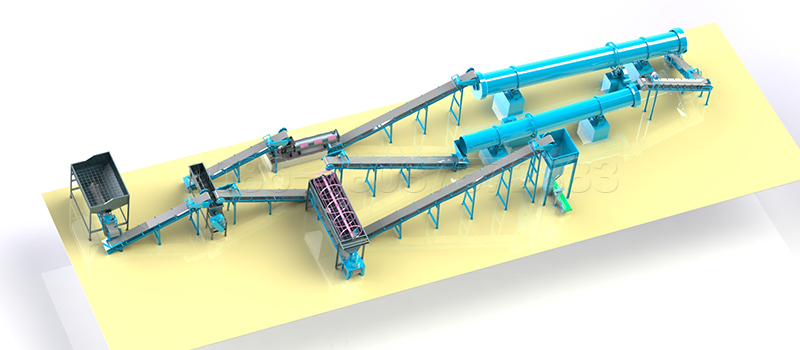

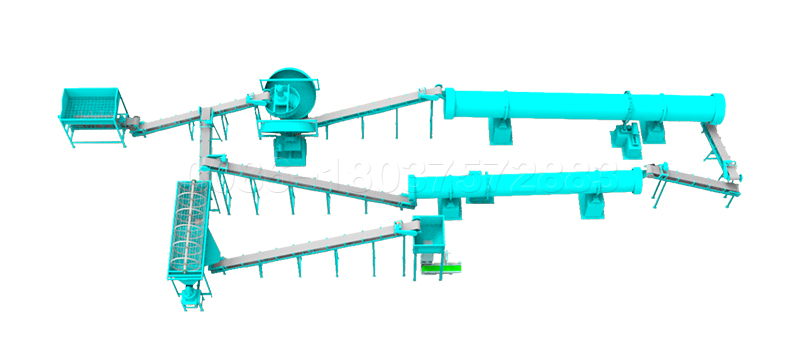

- Powdery fertilizer production from poultry waste: Composting process—Crushing and Screening process (make uniform powder) —Batching and Mixing process (strengthen fertilizer effect) —Packing process.

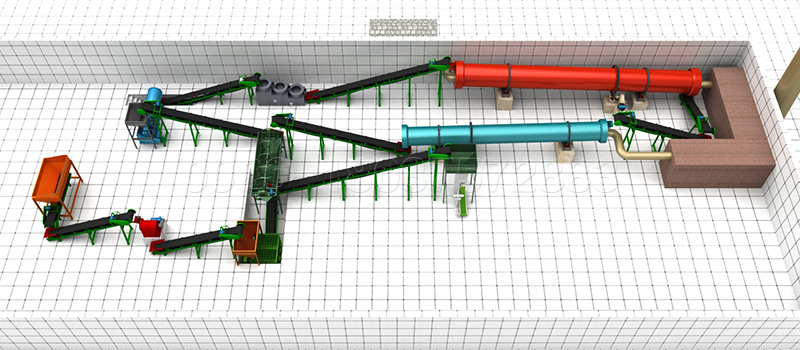

- Organic fertilizer pellets production from poultry waste: Composting process—Crushing and Screening process (to make uniform powder for granulating process)—Batching and Mixing process (adding nutrient elements and blend them evenly)— Granulating process (adopt wet granulation to make fertilizer pellets)— Drying and Cooling process (reduce moisture of pellets to 10% or less)—Screening process (select out unqualified fertilizer pellets)—Polishing process (make the pellets much rounder)—coating process (coat fertilizer pellets with anti-adhesion agent)—packing process (make bagged fertilizer)

Necessary equipment when you make commercial fertilizer from chicken manure

- Crushing equipment for make compost more inform and finer: New type vertical crusher and semi-wet material crusher are available. Both of them can crusher manure into set size.

- Rotary drum screen machine for selecting out unqualified materials: It can select out over-sized and small sized materials during fertilizer production, so as to guarantee smooth progress and fertilizer quality.

- Batching machine for adding needed nutrient elements: The former one can realize quantitative addition of needed nutrient elements.

- Mixing equipment to turner materials evenly: Here, horizontal mixer and disc mixer are available. They can mix two or more materials evenly.

- Poultry manure drying machine: It can reduce moisture of granulated fertilizer to under 10%. It also can be used for drying fresh poultry manure (13% moisture).

- Manure packaging machine: It is designed according to different characteristics of fertilizer powder and pellets, which has higher efficiency.

Poultry manure pellet machine— the essential equipment in fertilizer pellets production

Manure pellet machine is important in making organic fertilizer from animal manure. After granulating, animal manure compost will become spherical, which is convenient for transportation, storage and application. Here, you can adopt SEEC fertilizer pellet making machines.

- Disc granulator: It is featured with compact structure, easy operation and high granulation rate (93%). Its base adopts thickened and aggravated materials that can provide steady support for the whole machine.

- Newly developed organic manure granulator: By high-speed mechanical stirring force and generated aerodynamic force, new type granulator can make fertilizer pellets with higher hardness and beautiful appearance. In addition, there is three inspection windows, by which you can maintain replace quick-wear parts in time.

- Rotary drum stirring granulator: It is the patent product in SEEC. In addition to rotary shaft, its main body can also rotate. Therefore, it can finish mixing materials, granulating materials and polishing pellets.

What’s the project cost to manage poultry waste?

The project cost of managing poultry waste depends on the methods adopted. The composting and drying of poultry waste need fewer machines and less space. Therefore, the investment on them is less. Compared with composting and drying, commercial poultry manure fertilizer production needs much more machines, space and workforce. However, commercial fertilizer can create more profits for you. If you do not know how much will you spend on managing poultry waste. You can send your requirements to us (volume of poultry waste, site space and methods adopted), and our engineer will design most suitable plan and equipment selection for you.