Composting is the prior choice for most people to deal with animal manure, such as livestock manure and poultry manure. Because manure will become compost that contains necessary plant nutrients and can be used as organic fertilizer. In a nutshell, composting is a natural process, where microorganism decompose organic matters in manure to humus under controlled conditions. It is good for both soil and plants. Therefore, you can use it as base fertilizer on your own land, or you can produce marketable bagged organic fertilizer. For manure composting system, you can know about it from the following aspects, including composting process, composting methods, machines used in composting, composting conditions, and deep processing after composting.

What’s the complete composting process to convert manure to fertilizer?

If you want to compost animal manure (such as composting pig manure, cow dung composting and horse manure composting), you need to do the following works, including collect manure (and bedding) from barn, make a compost pile and turn them regularly until fermentation finishes. The detailed process is as below:

Collecting manure and adding auxiliary materials

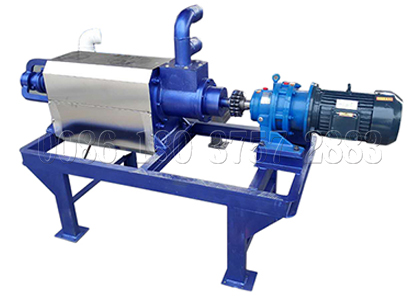

The first work to compost animal manure is to prepare raw materials. When you collect manure from barn, you can also collect spent bedding (which can be used as bulking agents and adjust C/N ratio). In addition, you can add some chopped straw or sawdust to manure. And the ratio of manure and addition usually is 3:1. For large scale or commercial manure composting, you also need to add extra fermentation strains, so as to guarantee enough microorganism content during composting. Meanwhile, you need to pay more attention to the moisture of manure, which will indirectly influence the oxygen content in the compost pile. If the water content of collected manure is too high, you can adopt SEEC manure separator to remove extra liquid. Because the suitable moisture for composting is 50% to 60%.

Making compost pile

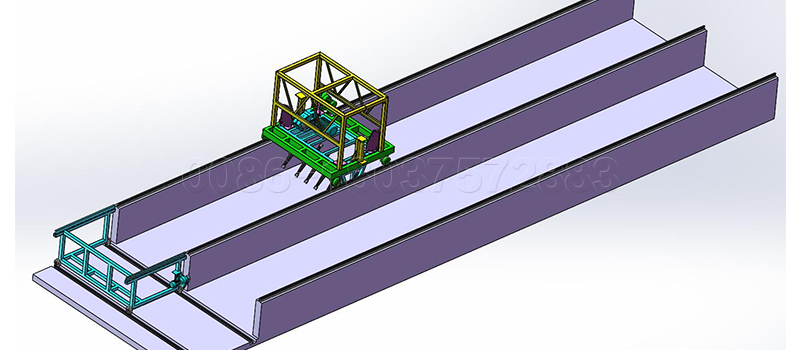

Both piling up raw materials on the ground in long rows and placing them in fermentation grooves are available. Making compost in long windrows needs larger space. The height of windrows ranges from 0.6 m to 1.8 m and the width ranges from 2 m to 3 m. If the compost pile is too small, it will be difficult for manure to heat up in short time, which will influence the composting process and compost quality. On the other hand, you can build some paralleled fermentation grooves to place organic waste. The depth of material in grooves usually is 0.8 m, 1.0 m,1.2 m or 1.5 m. Because compost turner is important in composting process, which can help you to adjust fermentation conditions. You can decide the size of compost pile according to the model of compost turner that you choose.

Turning compost pile regularly

After stacking materials together, the composting starts. In this process, microorganism generate amount of heat. On the one hand, the high temperature mean s the successful start of fermentation. On the other hand, too higher temperature will inhibit microorganism activities. Therefore, regularly turning compost pile is necessary. In the first week, the microorganism activity is strong, so you need to turn raw materials 2-3 time every day. In the following weeks, you can reduce to once every two days. The turning of compost pile not only can mix materials evenly and make fermentation more complete, but also add more oxygen for microorganism activity. Generally speaking, fermentation will finish in 20 to 30 days with the help of composting equipment.

What kind of manure composting system can you adopt?

According to our experience, efficient ways to compost animal manure include making compost pile and vermicompost. The former method includes windrow composting and composting animal manure in fermentation grooves. And the latter needs the involvement of earth worms.

Windrow composting & composting animal manure in fermentation grooves

You can pile raw materials in long rows, which is easy to arrange. You need to prepare enough space according to the volume of organic waste. In order to guarantee the quality of compost, you had better make a shelter if you make compost pile in the open air. What’s more, the ground shall be concrete, which can provide good working condition for compost turner and effectively prevent soil from pollution. In terms of the latter, you need build fermentation groove, which consists of three walls. The fermentation grooves usually are made up of bricks and cement. Compared with windrow composting, fermentation grooves can save space.

Vermicomposting

You can stack raw materials together and mix them evenly. Then, you should put earth worms in it. By the digestion of earth worms, organic matters in manure will become valuable vermicompost. To ensure the smooth progress, you should place compost pile with earth worms under shelter, and you can also cover it with straws, so as to keep the moisture of compost piles.

Composting manure quickly with SEEC manure composting equipment —large scale/small scale/windrow compost turner

Composting equipment is an important tool in manure composting system. As a manure to fertilizer equipment manufacturer, SEEC produces various kinds of compost turner with different working principles and models. All of them can shorten composting period and improve quality of compost. Now, let us know more about them. And you can choose suitable one to make your own manure composting system.

Large-scale commercial composting equipment with high output

SEEC wheel type compost turner and chain plate type compost turner have higher working efficiency and high output, so they are available for large scale compost production.

- Wheel type compost turner: It is suitable for turning compost pile with large span (as shown in the video). Its working depth can achieve 1.5 m to 3 m, and its working span can reach 30 m. During working process, you can monitor the compost turner by control cabinet. The tuning wheel adopts high-quality material, which has longer service life and stronger working capacity.

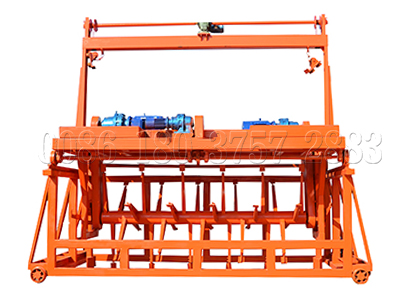

- Chain plate type compost turner: This kind of compost turner works on the fermentation groove, and can finish working for multiple grooves by transfer device. It adopts variable-frequency speed control system, which has a better adaptive ability to different kinds of organic waste. In addition, it can deal with organic waste stacked deeply, and make them contact with air thoroughly. What’s more, you can equip it with automatic discharge device, so as to improve working efficiency and provide convenience for subsequent operations.

Small-scale compost turner for farm manure management and small-scale organic fertilizer factory

For farm manure composting and composting work in a small-scale fertilizer factory, we recommend groove type compost turner and forklift type compost turner.

- Groove type compost turner: It works on the fermentation grooves. Its main parts include control panel, groove changing device (it can help compost turner move from one groove to other grooves) and electric cable winding wheel. In addition, you can equip it with water spray system, which can add water to compost pile during turning. Furthermore, its turning depth usually is 0.8m, 1.0m,1.2m and 1.5m. Its turning teeth adopt 16 Mn, which can turn raw materials evenly and crush caking.

- Forklift type compost turner: Its functions mainly focus on its bucket, which can finish crushing and mixing raw materials. The discharge port at the bottom of bucket adopts hydraulic control, which is easy to operate. You can use it in workshop or in the open air.

Windrow compost turner for composting manure quickly

Windrow composting is one of common manure composting systems. You just need to pile up organic waste in long rows. Meanwhile, space with a shelter will be better. Then, you can adopt windrow compost turner to regularly stir the compost pile, so that you can get quality compost in a short time. In addition, all windrow compost turner use diesel oil as fuel, which can provide more power to the whole machine.

- Crawler type compost turner: It adopts rubber track chassis, which can provide stable support during working. Its humanized design is the driver’s cab, which can separate worker from heat and odor generated from compost pile.

- Self-propelled compost turner: It is also called moving type compost turner. Its four wheels greatly increase its flexibility in operation. Its turning teeth can well turn and crush organic waste, so as to provide favorable environment for fermentation.

Moisture, temperature and oxygen—three essential factors for a successful manure composting system

During aerobic composting, oxygen-consuming bacteria and fungi will consume water, oxygen, nitrogen (N) and carbon (C), and produce nutrient-rich humus. Given this, you should strictly control the moisture and oxygen of the compost pile. Meanwhile, amount of heat will be generated during composting because of microorganism activity. However, when the temperature is above 60 degree centigrade, the microorganism will be affected and even inhibited. Thus, you should pay more attention to the three factors.

How to maintain suitable moisture?

The suitable moisture for composting is 50% to 60%. If you adopt fresh manure with higher moisture (such as manure cleaned by rinsing) to compost, you can adopt solid liquid separator to remove extra liquid. For fresh manure collected directly, you can adjust its moisture by adding some straw, sawdust and other organic wastes with stronger water absorbency. Besides adjusting moisture, as carbon-rich materials, straw and sawdust can also adjust C/N ratio of compost pile. Conversely, if the manure is dry, you need to add some water. One of easy methods for testing moisture is: Catch a handful of manure, if the manure can stick together in a ball without water droplets, that means moisture is suitable.

Adjusting temperature and oxygen content in manure composting system

The adjustment of temperature and oxygen occur during composting. During fermentation, microorganism will consume oxygen to convert organic matters into compost. Meanwhile, this process will produce amount of heat. If the temperature in the compost pile is too high, composting process will be affected due to the decrease of microorganism activity. The efficient method for dealing with this problem is to regularly turn the compost pile. With the turning of raw materials, the involvement of air will increase oxygen content and lower temperature. What’s more, this operation can mix raw materials evenly, so as to guarantee thorough fermentation.

Sometimes, other special conditions will appear, for example, there is no definite temperature rise for a long time. In such case, you should exam the moisture, C/N ratio and microorganism content of the compost pile. Too drier organic waste, lower C/N ratio and weaker microorganism activities will inhibit the fermentation.

Systems for you to make commercial organic fertilizer from composted animal manure

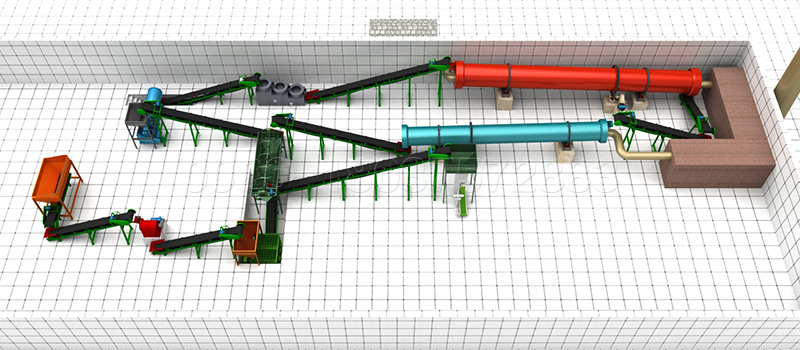

After composting, animal waste becomes nutrient-rich compost. After several days’ stabilization, you can apply it to plants and soil. In addition to personal use, you also can make commercial fertilizer from composted manure. There are two methods to make commercial organic waste. One is powdery organic fertilizer production and the other is granular fertilizer production. They have some differences on production process and manure processing machinery.

Powdery organic fertilizer production: Composting process (compost turner) —crushing process (vertical crusher) —screening process (rotary screen machine) —packing process (powdery fertilizer bagging machine)

Granular fertilizer production: Composting process (composting equipment) —crushing process (compost crusher)—screening process (compost screen)—granulating process (organic fertilizer granulator)—screening process (rotary screen machine for selecting out oversized and undersized pellets)—drying and cooling process (rotary drum drying and cooling machine)—packaging process (fertilizer pellets packing machine).