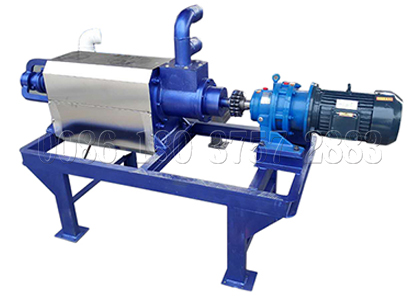

Pentru tratarea deșeurilor organice cu umiditate ridicată, primul pas este eliminarea apei suplimentare. Acest tip de deșeuri organice include gunoi de grajd de vacă, gunoi de grajd de porc și unele deșeuri agricole. Prin extrudare cu șuruburi, poate realiza deshidratarea deșeurilor organice. Tongda produce două tipuri de separatoare de gunoi de grajd, separator de lichid solid și ecran înclinat pentru separarea lichidului solid. Conform experienței noastre, rezumăm următoarele întrebări. Și sperăm că vă vor fi de folos.

1. Care este capacitatea separatorului de gunoi de grajd?

The input of organic waste: 8-15 metri cubi pe oră.

Producția de deșeuri organice deshidratate: 1.5-3 metri cubi pe oră.

2. What’s the materials of the whole machine?

All parts that contact with organic waste adopt SUS 304 ( such as hopper screen and auger).

3. Is it adopts explosion-proof motor ?

Yes.

4. Is the pressure (dehydrating level) increased by hand with tools or is it electric ?

You need to adjust the pressure of manure separator by hand with tools.

5. What’s the moisture of organic waste after dehydrating?

În general vorbind, it ranges from 25% la 40%. But you can adjust it according to your actual requirements.

6. What’s the hp of electric motor and the available voltage(110 V/220 V)?

The motor power is 4 Kw. The voltage can be designed and adjusted according your requirements.

7. What’s the size of liquid outlet hole?

Its diameter is 76 mm.

8. What’s the size of screen mesh?

Its size is 0.3-0.5 mm. And the customized size can achieve 0.1-0.3 mm.

9. Where can I use separated liquid from animal manure?

You can make bio-gas from it.

10. How to deal with organic waste after dewatering?

You can make a compost pile and produce organic waste compost, which can be used as organic fertilizer. Apoi, you can make bagged fertilizer powder or pellets for commercial purpose.

Nota: În timpul compostării, the content of animal manure is at least 60%.