Proizvodnja organskih gnojil je učinkovit način ravnanja z različnimi organskimi odpadki, zlasti za živalski gnoj. Po eni strani, komercialna proizvodnja gnojil iz živalskega gnoja je okolju prijazna in omogoča recikliranje gnoja. Na drugi strani, lahko vam ustvari več dobička s poceni živalskim gnojem. Za kmeta, ki želi narediti gnojilo iz svojih kmetijskih odpadkov, ali začetnik v industriji organskih gnojil, priporočamo majhno proizvodno linijo organskih gnojil. Je enostaven za uporabo in zahteva manj naložb.

Rešitev ena—Majhna linija za proizvodnjo gnojil iz komposta

V tovrstnem proizvodnem načrtu, boste dobili praškasto organsko gnojilo v vrečah. Glavni proizvodni proces organskih gnojil vključuje: kompostiranje organskih odpadkov(ubijejo škodljive snovi in izboljšajo absorpcijo hranil v živalskem gnoju )—drobljenje in sejanje komposta (naredite enoten in fin gnojilni prah)—mešanje z drugimi hranili(izboljša učinek gnojila, lahko izberete primerno zasvojljivost glede na potrebe po hranilih predmeta uporabe )— pakiranje(izdelava organskih gnojil v vrečah za prodajo). In potrebni stroji, ki se uporabljajo v majhni proizvodni liniji organskih gnojil, so:

Manjši stroj za obračanje komposta živalskega gnoja

S kompostiranjem, ti lahko uporabite gnoj kot organsko gnojilo. Na splošno, vse razgradljive organske odpadke je mogoče kompostirati. Vendar, priporočamo 60% živalski gnoj (vsaj) in 40% drugi organski odpadki v kompostnih kupih, tako da se zagotovi končna kakovost komposta. Lahko postavite živalski gnoj in material, bogat s C (zdrobljena slama, žagovina in riževa lupina, itd.) v fermentacijskih utorih. Nato se naš obračalnik komposta z utori premika po utorih in jih enakomerno obrača, tako da prilagodite temperaturo in ga prezračite. noter 20-30 dni, boste dobili kakovosten organski kompost.

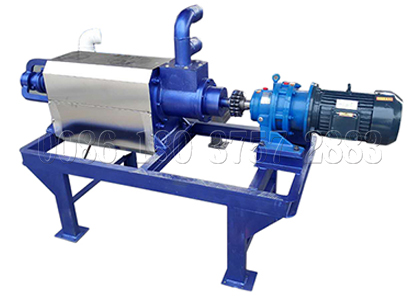

Opomba: Pred kompostiranjem, morate prilagoditi vlago 50%-60%, da zagotovite dobre pogoje za kompostiranje. Za gnoj z visoko vlažnostjo (kot so kravji iztrebki, konjski in prašičji gnoj), lahko sprejmete SEEC separator gnoja za odstranitev odvečne vode. Za perutninski gnoj z nižjo vlažnostjo, vlažnost lahko uravnavate z dodajanjem slame.

Drobilec komposta in sito za obdelavo manjšega gnojnega komposta

| Polmokri drobilnik materiala | Uvod | Rotacijski stroj | Uvod |

|---|---|---|---|

|

|

|

|

|

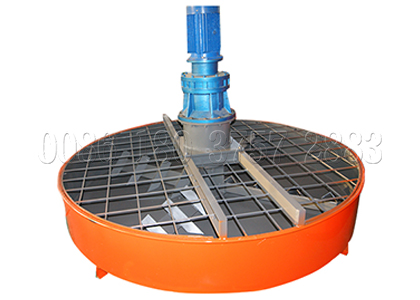

Manjši mešalnik organskih gnojil

Za komercialna organska gnojila, vsebnost hranil v kompostiranem živalskem gnoju ne more doseči standarda. Zato, morate dodati nekaj drugega hranilnega elementa, da izboljšate njegov učinek gnojila, kot so funkcionalne bakterije, humusna kislina in tako naprej. In SEECPJ-1600 jih lahko enakomerno premeša pred pakiranjem.

Stroj za pakiranje organskih gnojil v prahu

Stroj za pakiranje praškastih gnojil SEEC je zasnovan v skladu z značilnostmi praškastega materiala. Po eni strani, lahko učinkovito zavira blokado materiala. Na drugi strani, lahko kvantitativno stehta gnojilo v prahu, ter zaključno hranjenje in šivanje s pomočjo ene ali dveh oseb.

Opomba: Poleg zgoraj omenjenega stroji za izdelavo organskih gnojil v prahu, še vedno je nekaj dodatnih strojev. So transportni trak, oprema, uporabljena pred pakiranjem za začasno shranjevanje komposta in viličarski podajalnik.

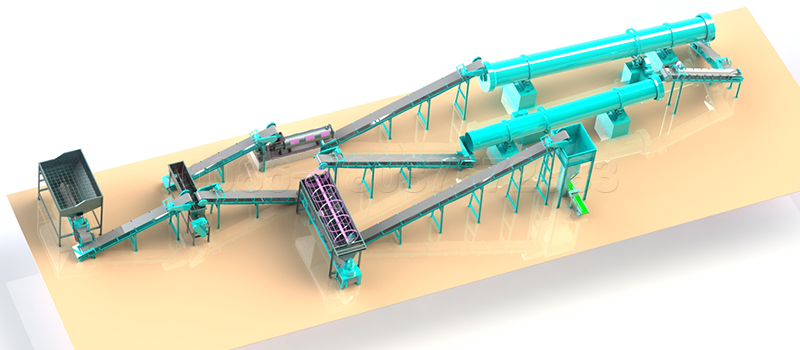

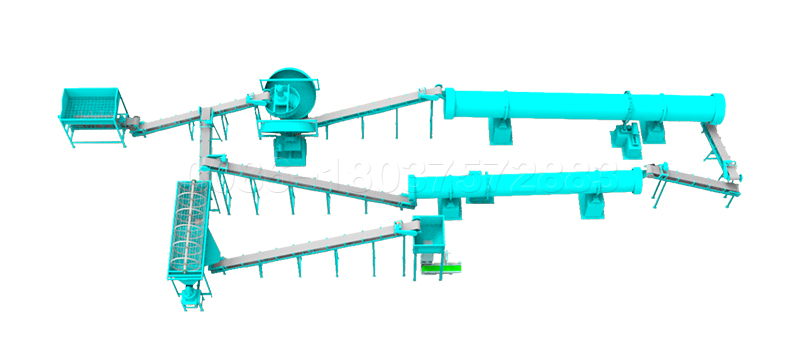

Rešitev dve—Linija za proizvodnjo gnojil v peletih z manjšo zmogljivostjo

V primerjavi s proizvodnjo gnojil v prahu, Proizvodnja gnojil iz gnojnih peletov je nekoliko zapletena. Toda gnojilni peleti iz živalskega gnoja so bolj priročni pri prevozu, shranjevanje in uporaba. Tukaj so podrobni proces in potrebni stroji za proizvodnjo organskih gnojil v majhnem obsegu:

Kompostiranje organskih odpadkov z majhnim obračalnikom komposta

SEEC manjši obračalnik komposta na valove vključuje obračalnik komposta na lastni pogon in obračalnik komposta na gosenicah. Oba lahko enakomerno obračata kompostni kup, tako da skrajšamo čas fermentacije 20-30 dni. Poleg tega, oba potrebujeta samo enega voznika za upravljanje in uporabo dizelskega goriva kot goriva. Primerni so za kompostiranje različnih živinskih gnojil in perutninski gnoj.

Drobljenje, Pregledovanje, postopek mešanja—Nov tip vertikalnega drobilnika, visoko učinkovit sito stroj in horizontalni mešalnik

Vsi ti trije postopki so priprave za postopek granuliranja. Postopek drobljenja in sejanja se uporablja za pripravo kompostiranega živalskega gnoja enotnega in drobnega. Gnojni kompost in zasvojenost bosta enakomerno premešana z mešalnikom gnojil SEEC.

- Nov tip vertikalnega drobilnika (SEECFLF-600): Njegova proizvodna zmogljivost je 3-5t/h. V notranjosti drobilnika so drobilne plošče in verige, ki lahko popolnoma zdrobi materiale v majhne delce. Kaj je več, velikost zdrobljenega materiala je nastavljiva. Na stroju je kontrolno okence, kar je priročno za vzdrževanje.

- Zaslonski stroj: Uporablja se lahko pred in po granulaciji. Pred granulacijo, lahko zagotovi enotnost in čistost komposta. Po granuliranju, lahko izloči prevelike in premajhne pelete, in jih pošljejo nazaj v sekundarno granulacijo s tračnim transporterjem.

- Horizontalni mešalnik: Proizvodna zmogljivost SEECWJ-7015 je 2-3 t/h. There are two rotors which can blend materials evenly.

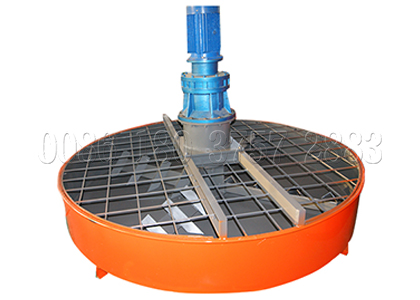

Granulating process with SEEC disc granulator/new type animal manure fertilizer granulator

Under the effect given by manure pellet making machine and water, animal manure compost will become spherical pellets in granulation process. Na splošno, the moisture of animal manure compost for granulating is about 30%. Both disc granulator and new type organic fertilizer granulator are suitable for manufacturing fertilizer pellets.

- Pan granulator: It utilize the centrifugal force generated from the rotation of disc and water to make quality fertilizer pellets. Poleg tega, it is easy to operate and its granulation rate can achieve 93%.

- Newly designed organic fertilizer granulator: It is the patent product in SEEC. It makes fertilizer into pellets by aerodynamic force produced by the rotation of turning tooth and proper moisture. Poleg tega, there are three inspection windows for you to maintain and replace turning tooth in time.

Packing process for making fertilizer of 25 kg/bag or 50kg/bag

V tem procesu, belt conveyor will send fertilizer pellets to packing machine. Potem, the equipment will finish weighing, feeding and sewing. You just need to designate one person to prepare bags and one person to make bags go through sewing device steadily. Kaj je več, there are single-bucket bagging machine in double-bucket bagging machine for you to choose. The latter can fill bags with fertilizer of different weight at the same time. You can select one of them according to your actual conditions.

Opomba: Optional organic fertilizer production equipment in small scale granular organic fertilizer production line—cooling and drying machine (to guarantee the moisture of granulated fertilizer is not more than 10%) and belt conveyor (to make sure continuous production).

How to start small scale organic fertilizer production business?

When you start a small scale organic fertilizer production business, you need to consider the following factors. Na ta način, you can produce salable organic fertilizer, make profits from animal manure and other organic wastes under lower investment.

- Know about source of organic waste and local requirements on organic fertilizer. You can collect raw materials for making fertilizer from places nearby your factory. If you have a farm, you can directly use wastes generated from your farm. Then you should investigate the requirements of local soil and plants on nutrients, so as to produce suitable fertilizer.

- Selection of site and equipment: Po eni strani, you can select a place to composting animal waste and produce organic fertilizer. Na drugi strani, the site should be far away from residential area, but it should have convenient traffic. For the equipment purchase and cost, you can inquire us.

What things need your more attention during building small scale organic fertilizer production line?

- For composting animal manure and placing compost piles, you should choose open sheds. Na ta način, good ventilation can dissipate odor of manure quickly. And sheds can prevent equipment from bad weather, so as to prolong their service life.

- The ground for placing equipment should be concrete, so as to provide steady support for operation of equipment. Ob istem času, it can efficiently prevent animal manure from polluting soil and water.

- You should to prepare a warehouse to place composted animal manure. Several days’ stabilization is necessary for fermented animal manure.

- In terms of the selection of organic fertilizer manufacturing machines, you can inquire professional manufacturer of manure to fertilizer equipment for advice. You can send your requirements to us, and our engineer can provide you detailed small scale organic fertilizer production plan, according to your budget, volume of raw material and site space.

How much about making small scale organic fertilizer production?

How to get low cost to get high capacity organic fertilizer production. There are several tips you should concern about producing small scale organic fertilizer production.

1. Covered area required for small scale organic fertilizer production line. As we known, small scale organic fertilizer production decides we should use small scale fertilizer line for small fertilizer plants. Obviously, how much land area required for small scale organic fertilizer production decides the cost of small scale organic fertilizer line. Which kind size of fertilizer equipment can be choose? Zato, it is the important factor in making small organic fertilizer production.

2. The way to obtain raw materials. As a businessman, the lowest cost can get high returns. If you have you own farms, the investment of fertilizer industry costs so low. medtem, it is the best condition to start small scale organic fertilizer business. Vendar, the materials you must buy from others, it can increase cost for you. Think about the problem seriously.

3. Optional fertilizer equipment suppliers. For organic fertiliser manufacturing, reliable manufacturers not a third agency is a key to succeed. For example, our company has our own factory, engineers, sales team to offer you professional and advanced technology and one-stop service with high quality. Končno, meeting your requirements is our final goal. Vendar, for a third parties agency, they can not offer you direct and effective service. Ob istem času, the quality reputation can not compare with fertilizer suppliers. The most important that is the price of products is higher. Zato, best manufacture can help you decrease budget. Why not choose our company? We are waiting for you .