Ravnanje s prašičjim gnojem je resen problem za prašičje farme ali nekatere tovarne za kompostiranje gnoja. Glede na odlično vsebnost hranil v prašičjem gnoju, kompostiranje je najprimernejši način ravnanja s prašičjim gnojem. Poleg kompostiranja, prašičji gnoj kompost proizvodnja gnojil je na voljo tudi za prašičjo farmo in večjo tovarno organskih gnojil.

Zakaj je ravnanje s prašičjim gnojem pomembno za vas?

Prašičji gnoj vsebuje veliko vode, ki se običajno skladišči v jami za gnojevko. Zaradi neprijetnega vonja in privlačnosti za muhe, dolgotrajno nalaganje prašičjega gnoja bo povzročilo onesnaženje okolja in prebivalcev. Na drugi strani, prašičji gnoj vsebuje veliko hranilnih snovi, kot je dušik, fosforja in kalija. Zato, lahko se uporablja kot dobro gnojilo za zemljo in rastline. S kompostiranjem ga lahko pretvorite v organsko gnojilo in proizvedete komercialno gnojilo iz prašičjega gnoja.. Na ta način, lahko učinkovito odstranite prašičje odpadke in zmanjšate lastne stroške gnojil ali ustvarite več dobička.

Kar zadeva ravnanje z odpadki iz prašičjih farm, kakšne rešitve lahko SEEC vam zagotoviti?

Svinjski gnoj vodenje na prašičji farmi lahko začne s kompostiranjem ali majhno proizvodno linijo kompostnih gnojil. Če želite samo pretvoriti prašičji gnoj v kompost za osebno uporabo, dovolj je kompostiranje. Majhna proizvodnja kompostnih gnojil je primerna za komercialno proizvodnjo komposta iz prašičjega gnoja. Lahko jih prodate drugim ljudem ali na trgih organskih gnojil. Podrobni koraki vključujejo:

Postopek kompostiranja v oknu

Kompostiranje v vitrini je enostaven in hiter način za kompostni prašičji gnoj. Samo zbrati morate prašičji gnoj in ga zložiti v vejice s pomožnimi materiali (žagovina in prah slame, itd.).

Ker prašičji gnoj spada med snovi, bogate z dušikom. Dodati morate nekaj materialov, bogatih z ogljikom (pin britje, sena in slame s stelje) ohraniti razmerje C/N (25:1/30:1). Nato jih morate enakomerno premešati, da bi zagotovili kakovost komposta. Tukaj, lahko posvojite obračalnik komposta v vitkih, katerih mešalna naprava lahko te materiale enakomerno premeša, in kompostni kup redno obračajte, da ustvarite ugodne pogoje za fermentacijo. V zgodnji fazi kompostiranja, morda boste morali obrniti kompost 1 oz 3 krat na dan. Dva tedna kasneje, lahko ga obrneš 1 vsaka dva dni. Obračanje kompostnega kupa bo prerazporedilo vlago, premaknite manj degradirane materiale s površine v notranjost kupa in sprostite dodatno toploto.

Postopek drobljenja

Namen tega koraka je izdelava enotnega in finega prahu. Ko se fermentacija konča, vsebnost vode v kompostu iz prašičjega gnoja je 25% do 30%. Velikost komposta je lahko nekoliko velika, in lahko pride do strjevanja zaradi dolgotrajnega sklada. Zato, kompost iz prašičjega gnoja morate po fermentaciji zdrobiti, ki lahko zagotovi tudi udobje za postopek sejanja. Na voljo sta navpični drobilnik novega tipa SEEC in drobilnik pol mokrega materiala.

Postopek presejanja

Postopek sejanja zagotavlja čistost in enotnost komposta iz prašičjega gnoja. Ker stroj za presejanje organskih gnojil ne more le izločiti nečistoč, temveč tudi ločiti večje delce. Tukaj, priporočamo vrtljivi stroj, katerih ravni presejanja je mogoče prilagoditi.

Postopek pakiranja

V procesu pakiranja, lahko naredite gnojilo iz prašičjega gnoja v vrečah. Ker je organsko gnojilo v vrečah priročno za uporabo, skladiščenje in transport. Tukaj, vreče z gnojili lahko napolnite in zaprete ročno. Lahko pa uporabite avtomatski pakirni stroj, ki lahko pakira gnojilo iz prašičjega gnoja v različnih težah (25kg/50 kg).

Sistem za odstranjevanje prašičjih odpadkov za pretvorbo prašičjega gnoja v koristno gnojilo

Kot vsi vemo, pretvorba prašičjega gnoja v koristno gnojilo je dober način za recikliranje prašičjega gnoja. Glede na proizvodni namen (za individualno uporabo ali komercialno proizvodnjo), nudimo vam tri sisteme za odstranjevanje prašičjega gnoja.

Proizvodnja komposta iz prašičjega gnoja

Ta sistem je za osebno uporabo. Samo kompostirati morate prašičji gnoj. Potem, lahko ga nanesete neposredno na svojo zemljo ali rastline. To je najpreprostejši in najcenejši način. In če želite hitro narediti kompost, dovolj je en obračalnik komposta.

Proizvodnja komposta iz prašičjega gnoja v vrečah

Kompostno gnojilo iz prašičjega gnoja pomeni praškasto gnojilo iz prašičjega gnoja. Njegova proizvodnja vključuje postopek kompostiranja, postopek drobljenja, postopek presejanja in postopek pakiranja. Med njimi, potrebna sta obračalnik komposta in drobilec komposta, in z delavci lahko dokončate druge procese.

Proizvodnja peletov gnojil iz prašičjega gnoja

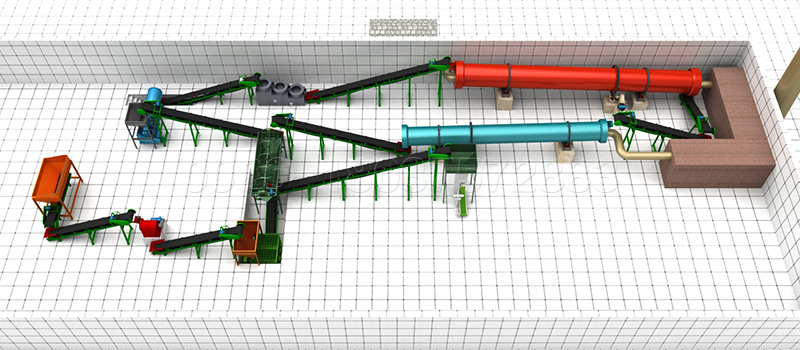

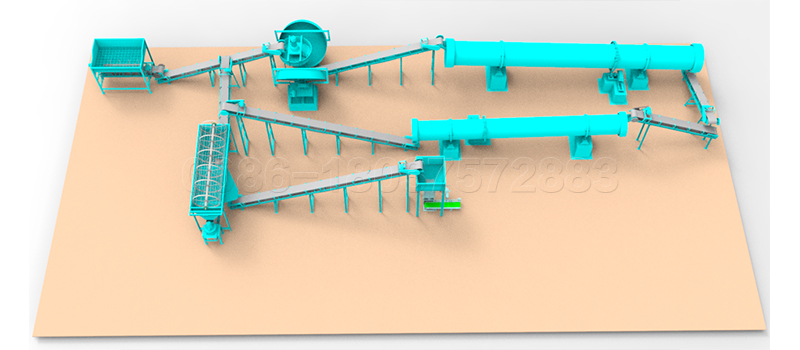

Je bolj zapleteno kot proizvodnja kompostnih gnojil. The celoten proizvodni proces je: postopek kompostiranja—postopek drobljenja—postopek presejanja—postopek granuliranja - postopek sušenja in hlajenja—postopek presejanja– postopek pakiranja. Lahko posvojiš različne kombinacije izdelkov za proizvodnjo peletov iz prašičjega gnoja, kot je drobilec komposta + sito za kompost + granulator gnojil za prašičji gnoj + oprema za sušenje in hlajenje + pakirni stroj; drobilec komposta + vrtljivo bobnasto sito + pan granulator + pakiranje, itd. Poljubno lahko izberete kateri koli stroj, glede na vaše dejanske pogoje (proračun, prostora, zahteve za končni izdelek).

Če želite prašičji gnoj spremeniti v gnojilo, kateri stroji vam lahko pomagajo in izboljšajo učinkovitost?

Kot ena izmed ekonomičnih metod za ravnanje s prašičjim gnojem, izdelava organskega gnojila iz prašičjega gnoja je odlična izbira. Za proizvodnjo visokokakovostnega gnojila iz prašičjega gnoja in izboljšanje učinkovitosti odstranjevanja, lahko dobite pomoč pri strojih za gnojenje. Prejšnji del nam pove tri sisteme odpadkov prašičev in podroben postopek. Tukaj, predstavili vam bomo ustrezne stroje.

Samovozni obračalnik komposta in obračalnik komposta na gosenicah za kompostiranje pri ravnanju s prašičjim gnojem

Nadalje, we can equip some auxiliary facilities for you, such as automatic sprinkling device. Končno, they are featured with low investment, low consumption and high production capacity.

Compost crusher and rotary screen machine for making uniform pig manure compost

Whether you want to make compost fertilizer or fertilizer pellets, you need to guarantee the uniformity of pig manure compost. Tukaj, you may need two machines, new type vertical crusher and rotary screen machine. The former utilizes chains and blades to crush caking and larger particles to ideal requirements. The rotary screen machine has different screening level, so that it can separate too small and too large particles out, so as to guarantee the uniformity of pig manure compost.

SEEC manure granulator for making organic fertilizer pellets from composted pig manure

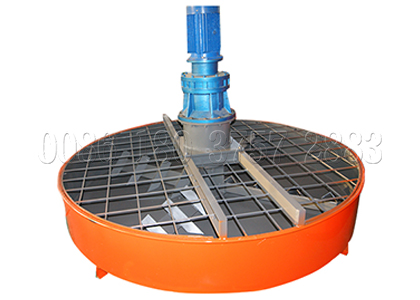

There are three types organic fertilizer granulator, which is available for making pig manure fertilizer pellets, disc granulator, new type pig manure fertilizer granulator and rotary drum stirring granulator. All them adopt wet granulation, and make fertilizer pellets by mechanical force and water. Disc granulator is most common granulator, which is low cost and easy to operate. New type pig manure fertilizer granulator makes fertilizer granules by mechanical stirring force, and its granulation rate can achieve 97%. The structure and function of rotary drum stirring granulator are more compact and stronger than the former two granulators. The pellets made by it is more beautiful and have higher hardness. Lahko izberete primernega, glede na vaše dejanske zahteve.

Rotary drum drying and cooling machines

Because mentioned granulator adopts wet granulation, you need to remove extra moisture to achieve standard moisture (below 15%). SEEC rotary drum drying and cooling machines can help you. The drying machine take away extra moisture by heating. Potem, the cooling machine will cool these pellets into ambient temperature, which is convenient for next process. Here you can build a hot blast furnace to provide heat for drying and dust collector to collect dust produced during drying and cooling. Poleg tega, you can use agricultural waste pellet fuel, coal or gas as the fuel to provide heat.

Automatic fertilizer packing machine for producing bagged pig manure fertilizer

For commercial production of pig manure fertilizer, packing is essential. In order to improve packing efficiency during pig manure management, we design two types fertilizer bagging machine, separately for compost fertilizer and fertilizer pellets. According to weighing method, it includes no-bucket (weighing when filling, which is a little slow) and bucket (filling after weighing, which is quicker) packaging machines. According to working efficiency, it includes single-bucket and double-bucket (which can fill bags with different scales at the same time). And according to packaging scale, it includes 25kg/bag, 50 kg/ bag and 1 ton/bag. In addition to pack organic fertilizer, it also suitable for grain, compound fertilizer and other industries.

What kinds of small pig manure fertilizer machines can you purchase from SEEC?

For small farm or beginner in organic fertilizer industry, we recommend small scale pig manure fertilizer production. All of our organic fertilizer making machines have small size. Poleg tega, if you have any special requirements, we can design pig manure management plan and customize equipment for you. And the small-scale pig manure fertilizer machines and their parameters are as below:

| Machine name | Model | Capacity (t/h) | Size(mm) |

|---|---|---|---|

| Semi-wet material crusher | SEECFLF-600 | 1-1.5 | 1200*1350*900 |

| Disc mixer | SEECPJ | 2-4 | 1600*1600*1600 |

| New type pig manure fertilizer granulator | SEECJZ-600 | 1-1.5 | 4100*1600*1150 |

| Small scale pan granulator | SEECYZ-1500 | 0.5-0.8 | 1760*1500*1950 |

| Rotary screen machine | SEECGS-1020 | 1-2 | Accept cutomization |

SEEC manure separator machine for pig slurry disposal

The high water-content makes pig manure management become more difficult. Zato, how to remove extra liquid from pig manure? SEEC manure separator can be you best choice. This manure separator utilizes screw extrusion to separate extra liquid. The dewatered pig manure will come out from one end of the machine.

Ob istem času, the liquid will flow out from the mesh on the cylindrical screen and discharge by pipe. The minimum moisture of dehydrated pig manure can achieve 30% do 40%. You can use it for making organic fertilizer or fish food. Poleg tega, this separator has strong decontamination ability, which can effectively prevent clogging and is easy to clean. Kaj je več, if you have much pig manure with higher water content (about 90%), you can also adopt SEEC inclined screen solid liquid separator. This kind of separator is featured with high output, easy operation and high efficiency. Like pig manure management, this separator is also suitable for dealing with other livestock manures, kot npr horse manure management in cow dung treatment.

How can you make special organic fertilizer from pig manure—bio organic fertilizer and vermicompost?

Bio organic fertilizer making for pig manure management

Composted pig manure belongs to quality organic fertilizer, which is nutrient-rich and has no adverse effect to soil. On this basis, you can also make bio organic fertilizer from pig manure. Po drobljenju, you can add functional bacteria by batching machine and blend them evenly. You can finish this operation manually. Or you can adopt SEEC batching machine and fertilizer mixer machine. For large scale bio organic fertilizer production and bio organic fertilizer pellets production, batching machine and fertilizer mixer are essential, which can improve working efficiency and guarantee fertilizer quality. Or you can add functional bacteria by pellets coating machine after granulating.

Vericomposting for pig manure disposal

Poleg tega, you can make vermicompost from pig manure as a method for pig manure management. You can pile up pig manure and straw together, and put earthworms into it. These earth worm will convert pig manure into excellent fertilizer by digestion. Kot vsi vemo, vermicompost is a kind of valuable organic fertilizer. When pig manure becomes vermicompost, you can make it into compost fertilizer or fertilizer pellets according to above mentioned process. As for the detailed layout, you can refer to this picture (If you have other requirements or problems, you can contact us).

When composting pig manure, you need to pay special attention to three factors

The composting process is the first step in pig manure disposal. Due to its influence on final quality of fertilizer, it is also the most key step. torej, you must pay more attention to various indicators. Med njimi, you should focus on moisture, temperature and oxygen content. medtem, this point is also important during dealing with other livestock manures.

Moisture control

Pred kompostiranjem, you should adjust water content of pig manure to 50% do 60%. You can add straw powder or sawdust, which has strong water absorption. Or you can use SEEC solid liquid separator to remove extra water. Because too wet will cause bad ventilation. Too dry will slow heating of compost pile. Med kompostiranjem, you can also sprinkle water according to actual conditions.

Temperature control

You should observe the temperature of compost pile by thermometer. You should turn the compost pile when the temperature reaches 50℃,. Because too higher temperature (above 65℃) will kill good bacteria and microorganism. V prvem tednu, you can turn the compost frequently, 2 do 3 krat na dan. During the later period of fermentation, you can reduce to 1 vsaka dva dni. Because the organic materials nearly run out in the final part. You can adopt compost turner, which can evenly blend outer pig manure and pig manure inside the compost pile.

Oxygen content control

Microorganism digest or decompose organic matters in pig manure while consuming oxygen. When the oxygen is deficient, the microorganism activity will slow. Zato, you should ensure the ventilation of compost pile. With the help of turning of compost turner, pig manure can fully contact with air. Ob istem času, the addition of air can also decrease the temperature of compost pile.