Organiese kunsmismasjien word hoofsaaklik gebruik om nuttige kunsmis uit organiese afval te maak. Die algemene organiese afval sluit veemis in, pluimvee mis, strooi, vinasse, suikerriet afval, olyfresidu, palm, klapper dop en so aan. Jy kan dit omskep in organiese kunsmis deur kompostering, verpletterend, granuleer en verpak. Die gedetailleerde werking en die nodige masjien vir die vervaardiging van organiese kunsmis in kunsmisvervaardigingsproses sal hieronder bekendgestel word.

Hoe om organiese afval in nuttige organiese kunsmis om te skakel?

Die maak van organiese kunsmis is die gewildste en doeltreffendste manier om organiese afval te hanteer. Wat moet jy doen om hierdie proses te voltooi?

- Die eerste stap is kompos. Dit kan skadelose behandeling realiseer, hoeveelheid vermindering, stabilisering van organiese afval. Dit is nodig om organiese afval saam met behoorlike grootte te stapel en dit gereeld met komposmaakmasjien te draai. Die hitte wat in die komposproses gegenereer word, sal skadelike stowwe in organiese afval doodmaak, soos patogeen, onkruidsade en eiers in dieremis. Ook, die volume en reuk van organiese afval sal geleidelik afneem, om gerief te bied vir berging en toepassing.

- Gekomposteerde organiese afval kan direk as basiskunsmis gebruik word. As jy kompos ryker aan voedingstowwe wil maak, jy kan komposkunsmis of organiese kunsmiskorrels produseer. Nadat ander voedingstowwe by organiese afval kompos gevoeg is, jy kan kwaliteit organiese kunsmis maak deur te meng, vertoning, granulering en verpakking.

Hoe help organiese kunsmismaakmasjien jou om kwaliteit kunsmis uit organiese afval te vervaardig?

Soos hierbo genoem, organiese kunsmis vervaardigingsproses sluit kompos en kommersiële organiese kunsmis produksie in. Die toediening van organiese kunsmismaakmasjien kan nie net afvalbestuur versnel nie, maar spaar ook arbeidsmag en verbeter kunsmiskwaliteit.

Toerusting vir die maak van kompos —Pas fermentasietoestande aan en versnel kompos

Ten einde organiese afval kompos suksesvol te maak, die volgende komposmaakmasjiene sal beskikbaar wees.

Komposdraaier—Draai, vermenging en verplettering van organiese afval

Komposmasjien is noodsaaklik vir die vermenging van komposhoop, om hitte in die middel van komposhope vry te stel en organiese afval te deurlug. Jy kan organiese afval in fermentasiegroewe of in lang rye plaas. Groeftipe komposdraaier word gebruik om organiese afval in fermentasiegroewe te draai. Sy draaitoestel kan klaardraai, vergruising en belugting van organiese afval. Kruiptipe komposdraaier en selfaangedrewe komposdraaier is geskik vir windry kompos. Hul stewige roterende as en draaiende tand kan komposhope eweredig meng en komposperiode verkort tot 20-30 dae.

Noot: Die draai van komposhoop kan ekstra hitte en vog vrystel en organiese afval deurlug. (geskikte temperatuur van die komposhoop is minder as 70 ℃, die suurstofinhoud van komposhoop moet meer wees as 5%.).

Vaste vloeistof skeier masjien—Verskuiwing van ekstra water uit organiese afval

Die geskikte vog van organiese afval vir kompos is 50% na 60%. Vaste vloeistof skeier kan ekstra water in organiese afval verwyder, veral vir diere-afval. Wanneer dit werk, pomp sal hoë-vog mis in die masjien stuur. Intussen, die algemene kombinasie van skroefekstrusie en skerm, die vog van uitset mis kan bereik 30%- 40%. Dus, ons noem dit ook misskeider.

Organiese afval breker—Maak organiese afval in klein stukkies

Ons breekmasjien vir organiese afval kan gekomposteerde organiese afval vergruis, strooi, gras en klein takke in klein deeltjies. Strooi en ander C-ryke materiale wat altyd as hulpmateriaal in kompos gebruik word, wat vog kan aanpas en deurlugting van komposhope kan verbeter. Met die oog op die grootte van strooi, vergruis voor toediening nodig is. Verder, jy kan ook organiese afvalkompos in klein stukkies fynmaak ná kompos, om gerief vir toepassing te bied.

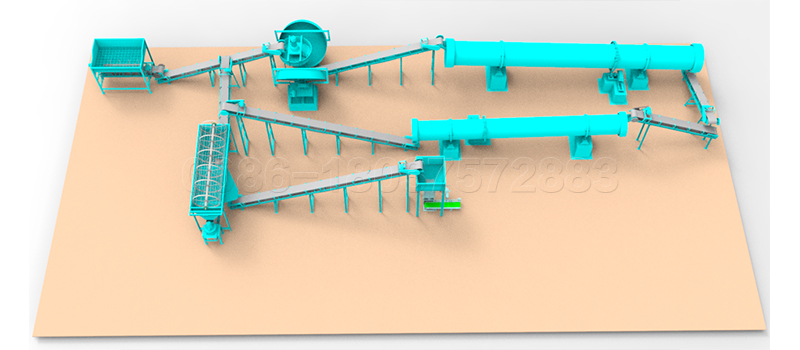

Masjiene vir die maak van kompos kunsmis—Die maak van kommersiële organiese bemesting met lae belegging

As jy baie organiese afval het om te hanteer, jy kan dit in kompos kunsmis maak na kompos. Die kompos kunsmis maak proses en ooreenstemmende organiese kunsmis maak masjien is: Verpletteringsproses (kunsmis maalmasjien) +Siftingsproses (kompos skerm masjien) + Batching en Meng Proses (mengmasjien en kunsmismengermasjien) +Verpakkingsproses (kunsmisverpakkingsmasjien).

Kunsmis maalmasjien—Maak fyn organiese kunsmispoeier

Om kwaliteit kompos kunsmis te maak, ons moet streng wees met elke klein deeltjie tydens kunsmisproduksie. Kunsmis maalmasjien kan koek en grootmaats in kompos tot klein deeltjies vergruis. Dit is ook belangrik in die produksieproses van organiese kunsmiskorrels. Dit maak voorbereiding vir granuleringsproses en handel oor ongekwalifiseerde kunsmiskorrels vir sekondêre granulering.

- Nuwe tipe vertikale breker: Dit gebruik kettings en lemme om koek in klein stukkies te verpletter. Sy produksievermoë wissel van 3t/h tot 15t/h, which is suitable for both small scale organic fertilizer and large scale organic fertilizer production line. There is an inspection windrow for you to check the inner conditions of crusher.

- Semi-beet materiaal breker: It can deal with organic waste with higher moisture. Its special design can prevent blockage of organic waste or compost. Its output ranges from 1t/h to 8t/h. Wat is meer, crusher with the same capacity can be designed into one crushing stage or two crushing stages.

- Hammer crusher: It adopts high-speed hammer and screen to make organic wastes or compost into small pieces. Tydens werk, qualified materials will go through screen and go into next step. Larger particles will be ground until they can pass through the screen.

Compost screen machine—Making uniform and pure organic fertilizer powder

Compost screen machine in compost fertilizer production can guarantee the purity and uniformity of compost. You can also use it before and after granulation process in fertilizer pellets production line. Its function is to guarantee the uniformity of products. Rotary screen machine is the prior choice in fertilizer production. You can choose screening level (two or three discharge port) and the size of final product (by the diameter of sieve holes) Volgens u werklike vereistes.

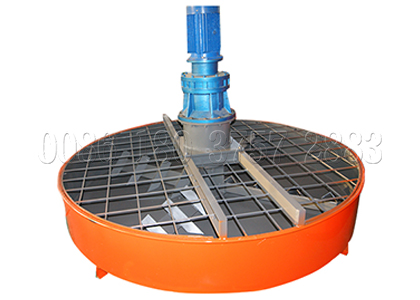

Batching machine and fertilizer mixing machine—Adding other nutrients to compost

You can add other nutrients or materials to organic waste compost by batching machine. Our dynamic batching system can automatically finish proportional supply of materials. Ook, it can complete uninterrupted production, so as to keep higher working efficiency. There are two or more stock bins for you to choose. All these materials will be sent to fertilizer mixer machine. Fertilizer mixer machine will blend multiple materials evenly, so as to make uniform fertilizer effect. There are horizontal mixer and disc mixer for you to choose. Both of utilize stirring shaft to blend these materials. Their capacity is 2t/h-12t/h.

Compost fertilizer packing machine—Producing bagged compost fertilizer

Compost kunsmisverpakkingsmasjien is designed for package powdery materials. There is small belt feeder inside the packing machine, which can guarantee smooth discharge. Compost fertilizer enters bags from packaging machine after weighing. And then the sewing device will seal fertilizer bags. The fertilizer bagging machine can greatly improve packing accuracy and speed.

Granular organic fertilizer production equipment—Making uniform fertilizer pellets efficiently

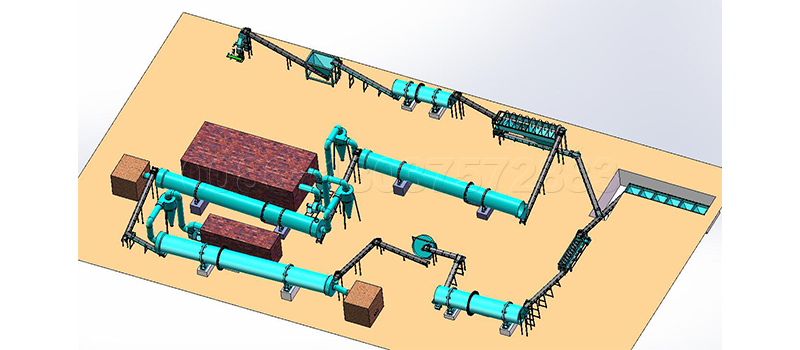

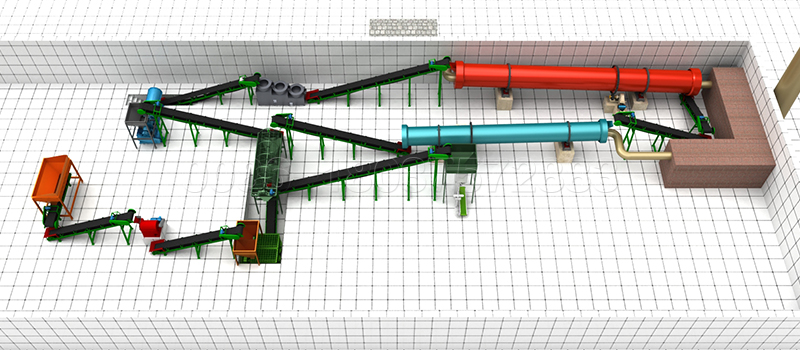

Granular organic fertilizer production is more complex compost fertilizer production. The complete process of making organic fertilizer pellets includes: Verpletteringsproses (kunsmis maalmasjien) +Siftingsproses (kompos skerm masjien) + Batching en Meng Proses (mengmasjien en kunsmismengermasjien) + Granulation Process (compost pellet machine) + Drying and Cooling Process (fertilizer drying machine) + Polishing and Coating Process (fertilizer polishing machine and coating machine)+Verpakkingsproses (kunsmissakmasjien). Besides works for making fertilizer pellets, other processes are same with that of compost fertilizer production. And main machines for making fertilizer pellets are:

Fertilizer granulator machine—Producing quality and uniform organic fertilizer pellets

After former processing, conveyor belt sends compost into fertilizer pellet making machine. With the help of mechanical force and proper moisture, organic fertilizer granulator machine can make composted organic waste into spherical pellets. The most popular compost pellet making machines include:

- Pan granulator: Stable pedestal, solid granulating disc and adjustable inclination angle of main body jointly make uniform fertilizer pellets. When compost enters disc granulator, it will gradually become small particles under the action of centrifugal force and steam. There is a scraper plate, which can automatically clean compost stuck on the bottom of pan.

- New type organic fertilizer granulator: It utilizes the continuous work of rotary shaft with stirring tooth to make compost into pellets. As the patent organic fertilizer making machine in our company, it can effectively make beautiful and uniform fertilizer pellets. There are inspection windows for you to check and maintain inner parts.

Fertilizer drying machine and cooling machine—Making pellets achieve standard moisture

Oor die algemeen gesproke, water addition will occur in fertilizer granulation process. Nietemin, there is strict moisture control on commercial organic fertilizer pellets, whose moisture should be lower than 10%. Fertilizer drying machine utilize hot air to take away extra moisture from fertilizer pellets. Destyds, rotary cooling machine will adopt induced draft fan and air to reduce the temperature of dried pellets. The capacity and model of organic fertilizer making machine are adopted according to the actual output of whole fertilizer production line. Wat is meer, there is dust collector system to deal with dust produced from drying and cooling process. Op hierdie manier, the air can be directly released into the atmosphere.

Fertilizer pellets polishing machine and coating machine—Optional organic fertilizer making machine

The application of polishing and coating machine is to make fertilizer pellets more beautiful and uniform. The polishing machine will utilize the centrifugal force generated from high-speed rotation to make fertilizer pellets rounder and more uniform. Ook, you can use coating machine to coat fertilizer pellets with functional strains, anti-blocking agent and so on. These two kinds of organic fertilizer making machines are optional, you can choose them according to actual requirements on fertilizer production.

Granular fertilizer bagging machine—Finishing quantitative packaging

Our granular fertilizer bagging machine is designed according to features of fertilizer pellets, which can effectively prevent blockage. Ook, this packing machine can finish weighing and filling fertilizer pellets. And we can equip it with sewing machine to improve working efficiency. It can achieve automatic and quantitative package, which can greatly improve production efficiency. For large scale organic fertilizer production, we also recommend palletizing machine which can orderly pile up fertilizer bags together. Op hierdie manier, workforce and time will be saved.

Small scale organic fertilizer making machine for you to start organic fertilizer business

Small scale organic fertilizer making machines is suitable for dealing with organic waste of smaller volume or a beginner in organic fertilizer industry. From composting to deeply processing organic waste, we can provide you various organic fertilizer making machine. As a fertilizer equipment manufacturer, we produce fertilizer maker machines with 0.5t/h-2t/h for small scale organic fertilizer production. Small scale organic fertilizer production line is featured with lower investment, smaller installation area and less human input. Dit wil sê, the cost of organic fertilizer production line in small scale is lower. If you do not know how to choose organic fertilizer making machine with suitable capacity, our engineer can offer you organic fertilizer production project proposal. Choosing our organic fertilizer equipment to start your own organic fertilizer business.