Ang pag-compost ay isang mabisang paraan upang gawing organikong pataba ang dumi ng kabayo. Sa pamamagitan ng pag-compost, papatayin ang mga parasito at mga buto ng damo sa sariwang dumi ng kabayo. Pagkatapos makakuha ng de-kalidad na pataba ng kabayo compost, maaari mo itong gamitin nang direkta o gumawa ng komersyal na pataba ng pataba ng kabayo. Mayroon kang dalawang pagpipilian, horse manure compost fertilizer production at horse manure fertilizer pellets production. Mahahanap mo ang mga detalyadong pamamaraan at kapaki-pakinabang na makina sa mga sumusunod na bahagi.

Propesyonal na plano sa pamamahala ng dumi ng kabayo para sa iyo na gawing pataba ang dumi ng kabayo?

Ang isang wastong plano sa pamamahala ng dumi ng kabayo ay kinakailangan para sa iyo na harapin ang dumi ng kabayo, lalo na para gawing pataba ang dumi ng kabayo. Ito ay magagamit para sa pamamahala ng basura sa bukid at komersyal na paggawa ng pataba. Dito, ipapakilala namin sa iyo ang isang propesyonal at kumpletong plano sa pamamahala, pag-compost ng dumi ng kabayo— paggawa ng pataba ng pataba ng kabayo o fertilizer ng pataba ng kabayo. Una, dapat kang maghanda ng angkop na espasyo para sa pag-compost ng dumi ng kabayo at kasunod na proseso ng pag-aabono ng dumi ng kabayo.

Ang lugar para sa pag-compost ay maaaring kalkulahin ng formula: lugar ng composting= oras-oras na output* oras ng pagtatrabaho*panahon ng fermentation/ang density ng mga materyales/taas ng compost pile o lalim ng stacked manure. Kung gusto mo lang gumawa ng compost ng pataba ng kabayo, matatapos ang mga gawain dito. Sa mga tuntunin ng komersyal na paggawa ng pataba ng pataba ng kabayo, dapat kang gumawa ng isang pagawaan malapit sa fermentation area upang ilagay ang kabayo mga makina sa paggamot ng pataba.Maaari kang gumawa ng pulbos ng pataba ng pataba ng kabayo at linya ng produksyon ng mga pellet o pareho ng mga ito. Ang mga detalye ay ang mga sumusunod.

Mga pamamaraan sa pag-compost ng dumi ng kabayo

Ang pag-compost ay ang una at pinakamahalagang hakbang sa paggawa ng pataba ng pataba ng kabayo. Para sa kalidad at matagumpay na compost, dapat mong gawin:

1.Mga materyales sa paghahanda

Para sa sariwang pataba ng kabayo, kailangan mong ayusin ang moisture nito sa 50% sa 60% ni say liquid manure separator. Bilang karagdagan, maaari kang magdagdag ng ilang mga pantulong na materyales para ayusin ang kahalumigmigan, C/N ratio at pagbutihin ang bentilasyon ng compost pile, tulad ng kumot, dayami pulbos, sup, rice hull powder at iba pa.

2.Itambak ang dumi ng kabayo sa tamang sukat

Pagkatapos maghanda ng mga materyales, kailangan mong paghaluin ang mga ito nang pantay-pantay at itambak ang mga ito sa mahabang hanay o ilagay ang mga ito sa fermentation grooves. Ang dating pamamaraan ay nangangailangan ng malaking espasyo at patag na lupa. At ang huli ay nangangailangan sa iyo upang bumuo ng mga grooves ng pagbuburo, na binubuo ng tatlong pader.

3.Regular na iikot ang mga materyales

Ang pag-compost ay a biological decomposition proseso. Ang mga mikroorganismo ay magko-convert ng mga organikong bagay sa mga sustansya sa pamamagitan ng pag-aakala ng oxygen at moisture. Kasabay nito, malaking halaga ng init ang bubuo, na maaaring pumipigil sa aktibidad ng microorganism at pumatay pa nga ng mga kapaki-pakinabang na bakterya. Ang regular na pag-ikot ng compost pile ay maaaring magbigay ng sapat na oxygen para sa pagbuburo, ayusin ang temperatura at paghaluin ang mga materyales sa lahat ng bahagi nang pantay-pantay. Ibig sabihin, ang pag-ikot ng compost pile ay magbibigay ng mga kanais-nais na kondisyon para sa pagbuburo, upang mapabilis ang panahon ng pag-compost at pagbutihin ang kalidad ng compost. Kapag natapos na ang composting, bababa ang dami ng compost pile, ang orihinal na amoy ay mawawala at ang dumi ng kabayo ay magiging maluwag at itim. Pagkatapos, maaari mo itong gamitin bilang pag-amyenda ng lupa at pataba para sa mga halaman.

SEEC composting machine para sa mabilis compost

Ang regular na pag-ikot ay maaaring gumawa ng pataba ng kabayo na ganap na makipag-ugnay sa oxygen, na parehong maaaring magpababa ng temperatura at mag-alis ng kahalumigmigan. Pinapalitan ang workforce ng mga makinang pang-compost maaaring higit na paikliin ang panahon ng pag-compost at makatipid sa gastos sa paggawa. Dito ay ipakikilala natin ang tatlong uri ng horse manure composting machine.

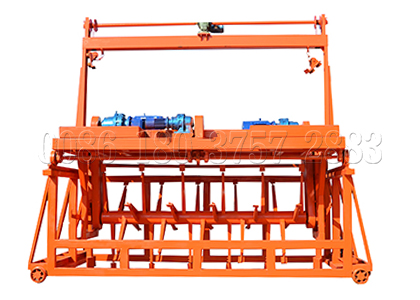

Horse manure windrow composting machine (20-30 araw ng panahon ng pagbuburo)

Matapos itambak ang dumi ng kabayo at bulking agent sa mahabang hanay, maaaring patakbuhin ng isang driver ang windrow compost turner para iikot ang compost pile. Parehong self-propelled compost turner at crawler type compost turner ay kabilang sa compost windrow turner. Maaari silang sumaklaw sa ibabaw ng compost pile. Kapag umusad sila, ang kanilang mga kagamitan sa pagliko ay pukawin ang dumi ng kabayo upang muling ayusin ang compost pile. Ang self-propelled compost turner ay may apat na gulong, na nababaluktot habang nagtatrabaho. Ang crawler type compost turner ay gumagamit ng rubber track chassis, na steady sa panahon ng operasyon.Ano pa, maaari mong bigyan ang mga ito ng spray system, na maaaring magdagdag ng tubig sa compost pile anumang oras. May taksi sa compost turner, na maaaring paghiwalayin ang amoy at mataas na temperatura. Ang makatao na disenyong ito ay nagbibigay ng magandang kapaligiran para sa operator. Sa wakas, pareho sa dalawang compost turners ay diesel-driven.

Mag-ukit na uri ng horse manure composting machine (20-30 araw ng panahon ng pagbuburo)

After placing horse manure in fermentation grooves, the groove type compost tuner will move on the paralleled walls to turn the horse manure. The stirring apparatus on the groove type compost turner will make the manure contact with air fully. You just need designate one person to start up and close down the compost turner on the control cabinet. Furthermore, there is shift machine, which can help you to move groove type compost turner from one groove to another groove.If you have large scale manure to dispose, you also can choose wheel type compost turner and chain plate type compost turner.

Fermenting horse manure by in vessel composter (7-10 araw ng panahon ng pagbuburo)

In vessel composter belongs to automatic composting machine, which can finish horse manure composting in 7 sa 10 days. Its fermentation volume ranges from 5m3 sa 150 m3. After putting mixed materials to in vessel composter, it will automatically control fermentation conditions and finish composting. There is PLC control cabinet, you can monitor fermentation conditions from it. The stirring apparatus inside the composter will periodically turn the materials, and the air supply system can provide enough oxygen.In addition, there is deodorization system, which can effectively deal with odor and other gases produced by fermentation. When the fermentation finishes, you can get quality horse manure compost from the discharge port. After several days’ stabilization, you can use it directly to soil and plants or for commercial organic fertilizer production.

How to make compost fertilizer production from horse manure?

Horse manure compost fertilizer production is an easy way to make commercial organic fertilizer. In terms of low cost and easy operation, compost fertilizer production line is a popular choice for small horse farm or small organic fertilizer factory. The detailed steps and necessary machines include:

1.Crushing horse manure compost with new type vertical crusher: Crushing process is used for deal with caking or bulks in horse manure compost, so as to guarantee uniformity of fertilizer. SEEC vertical crusher adopts blades and chains to crush caking into small particles.

2.Screening compost with rotary screen machine: Screening process is used for further making uniform compost powder. Rotary screen machine can be designed with two or more screening levels, which can make more uniform and pure fertilizer compost.

Procedures and machines for making commercial horse manure fertilizer pellets

In addition to horse manure fertilizer powder, you can also produce horse manure fertilizer pellets. Since the fertilizer pellets are convenient for transportation, storage and application, its production process is more complex and stricter.

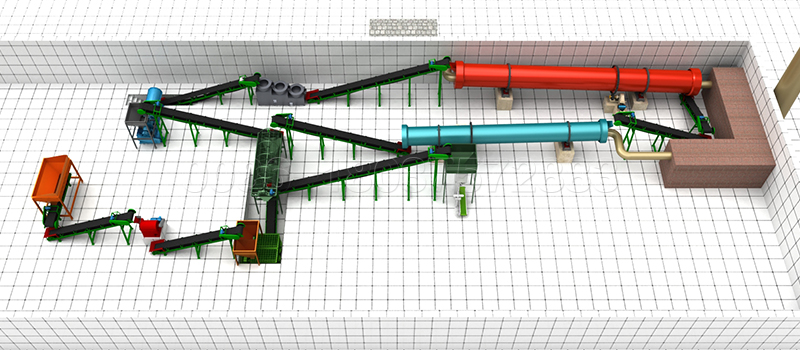

The complete procedures to make granular horse manure fertilizer

Crushing process (eliminate caking and make uniform compost) —screening process (select out compost with unqualified size, so as to provide uniform particles for granulation) —[mixing process (add other materials to horse manure compost and mix them evenly, so as to improve fertilizer effect)] —granulating process(make fertilizer pellets by mechanical force and water)—drying and cooling process (take away extra moisture of fertilizer pellets by hot air and cool them down to ambient temperature)—

—screening process (to guarantee the uniform of fertilizer pellets)—[polishing process (in order to make the appearance of fertilizer more beautiful) — coating process (you can coat pellets with functional bacteria, anti-blocking agent and so on)] — packing process (make bagged fertilizer).

Multiple fertilizer pellets making machines for you to choose

We will introduce all machines that may be adopted here, and you can choose and combine different machines for production. All of these machines play different roles in the fertilizer pellets production. And they are suitable for dealing with other manures, such as chicken manure fertilizer making, goat manure compost fertilizer production at iba pa.

Compost crusher and screening machine

After long-term stack, there must be bulk or caking in the compost pile. Compost crusher is designed for eliminating caking and produce fine and uniform compost. The crushing device inside the compost crusher can well crushed horse manure compost into small particles. There is new type vertical crusher, semi-wet material crusher and hammer crusher (for large scale production) for you to choose. Because granulating process has higher requirements on the uniformity of compost, you had better adopt screening machine to select out smaller or larger compost particles. SEEC rotary screen machine have two or more screening levels, which can meet your different requirements on size of compost powder. Bilang karagdagan, screening machine can also be used after granulating, which can select out unqualified fertilizer pellets.

Batching machine and mixing machine

Different application objects have different requirements on nutrients. Samakatuwid, you may need to add some other elements to horse manure to increase its function. The function of batching machine is to continuously provide a certain number of elements for mixing. And you can adjust the parameters of batching machine. Kasabay nito, the mixing machine is responsible for mix these materials evenly. And the conveyor belt will send mixed materials to granulator. There are horizontal mixer and disc mixer for you to blend materials evenly. Both of them can blend materials evenly in short time.

Horse manure fertilizer granulator

All SEEC granulators adopt wet granulation.

| SEEC granulator | Features and information |

|---|---|

|

|

|

|

|

|

|

|

|

Rotary drum drying and cooling machines

The standard moisture for final fertilizer pellets product is less than 15%. The moisture of pellets will increase during granulating process, because of the involvement of water. Samakatuwid, you should adopt rotary drum drying machine to remove extra moisture. Meanwhile, the rotary drum cooling machine is used for cooling pellets down to normal temperature, so as to provide convenience for screening and packing. And there are some auxiliary machines, including hot blast furnace for providing hot air and dust collector.

Polishing and Coating machines

Polishing machine can make horse manure fertilizer pellets more beautiful and uniform by centrifugal force generated from high-speed rotation. It is an ideal machine for fertilizer pellets making. Coating machine is used for spray some anti-blocking agent, functional bacteria and sustained-controlled release preparation on the surface of fertilizer pellets. What’s more, it can also coat compound fertilizer with different colors. In terms of their functions, they are also necessary in large commercial production.

Horse manure pellets packing machine

The horse manure pellets packing equipment includes single-bucket packing scale and double-bucket packing scale. Compared with single-bucket bagging machine, double-bucket packing machine can feeding bags with different amounts of pellets in turn. For example, you can produce 25kg/bag and 50kg/bag horse manure fertilizer at the same time. Single-bucket packing scale is usually suitable for small scale fertilizer production. Both of them can automatically finish feeding, filling and sewing fertilizer bags.

Horse manure high position manipulator palletizing machine with high efficiency

After packing process by fertilizer bagging machine, palletizing machine can help you solve carry problem. It adapts professional servo control system to simplify the manipulator. The control system can set up different palletizing modes according to your needs. That means the number of stacking layers and the number of pallets per layer can be easily controlled by your requirements. Compared with manual palletizing machine, it is harder to collapse and looks neat and beautiful. Bilang karagdagan, the structure of operation is simple and convenient. However, the most important point is that the cost is lower than manual palletizing machine.

SEEC advice for you to make own organic fertilizer plant from horse manure

If you want to build a horse manure fertilizer plant on your farm, or you just a beginner in organic fertilizer industry, we can give you some professional instruction and advice on building organic fertilizer plant. And we will analyze this problem from the following two aspects.

What should you prepare before making fertilizer plant?

- Raw material: It is the first factor that needs your special attention. If you breed horse, you can collect horse manure from your own farm. By building a horse manure fertilizer plant, you not only find a good way to deal with horse manure and barn bedding, but also get extra income. If you do not have direct raw material source, you should collect it from nearby places to save cost.

- Site for building fertilizer plant: For house farm, you can build the fermentation site and production line on the farm. Or you should build a plant that close to raw materials source. Bilang karagdagan, the ground for building fertilizer plant should be flat and concrete.

- Selection of fertilizer making machines according to requirements on final fertilizer product: The final product and its output decide the selection and preparation of fertilizer production equipment.

Note: If you do not know how to calculate the area of fertilizer plant and the preparation of fertilizer making equipment, you can tell us your conditions and requirements to us. And our engineer will provide you a detailed production design.

Starting an organic fertilizer plant from small scale manure fertilizer production line

For horse farm and beginner, we recommend small scale compost fertilizer production line. On the one hand, the circle of production is short and efficient (composting—crushing—screening —packing), and it occupy less space. On the other hand, the investment of small-scale production line is low and the application is wide. You can produce commercial fertilizer from all decomposed organic waste available in short time with low cost. Sa wakas, you can directly sell them in nearby places, which is convenient for transportation and application. Sa isang salita, small scale compost fertilizer production will be your first choice to start organic fertilizer plant. This method is also suitable for fertilizer production from other organic wastes.