He huarahi whai hua te mahi wairākau ki te huri i te hamuti hoiho hei tongi waro. Ma te wairākau, ka patua nga kakano pirinoa me nga taru i roto i nga hamuti hoiho hou. I muri i te whiwhi wairākau hamuti hoiho kounga, ka taea e koe te whakamahi tika, te hanga tongi hamuti hoiho arumoni ranei. E rua nga whiringa, te mahi tongi whakawairakau hoiho me te hanga pire whakawairakau hoiho. Ka kitea e koe nga tikanga taipitopito me nga miihini whai hua i nga waahanga e whai ake nei.

Mahere whakahaere para hamuti hoiho ngaio hei huri i nga para hoiho hei tongi?

Ko te mahere whakahaere para whakawairakau hoiho e tika ana mo koe ki te whakahaere i nga hamuti hoiho, otira mo te huri i te hamuti hoiho hei tongi. Kei te waatea mo whakahaerenga para paramu me te mahi tongi arumoni. Konei, ka whakamohiohia e matou he mahere whakahaere ngaio me te whakaoti, whakawairakau hoiho whakawairakau— te hanga tongi whakawairakau hoiho he pelleti tongi hamuti hoiho ranei. Matua, me whakarite e koe he waahi pai mo te whakawairakau maara hoiho, me te mahi whakawairakau hoiho.

Ko te waahi mo te wairākau ka taea te tatau ma te tauira: waahi wairākau= te whakaputanga haora* haora mahi*te wa FERmentation/te kiato o nga rawa/te teitei o te puranga wairākau, te hohonutanga ranei o te whakawairakau.. Ki te hiahia noa koe ki te hanga wairākau hamuti hoiho, ka mutu nga mahi i konei. Mo te hanga tongi hamuti hoiho arumoni, me hanga he awheawhe tata ki te waahi FERMENTATION ki te tuu hoiho nga miihini maimoatanga hamuti.Ka taea e koe te mahi tongi tongi hoiho te paura me te raina whakaputa pire, e rua ranei. Ko nga korero e whai ake nei.

Nga tikanga ki te wairākau para hoiho

Ko te mahi wairākau te mahi tuatahi me te mea nui i te wa e mahia ana te mahi tongi hamuti hoiho. Mo te kounga me te wairākau angitu, me mahi koe:

1.Nga rauemi whakarite

Mo te hamuti hoiho hou, me whakatika e koe tona makuku ki 50% ki 60% na she whakawehe whakawairakau wai. Hei taapiri, ka taea e koe te taapiri i etahi rauemi awhina hei whakatika i te makuku, C/N ōwehenga me te whakapai ake i te hau o te puranga wairākau, penei i te moenga, paura kakau witi, puhu wahie, paura takere raihi me etahi atu.

2.Whakanohoia nga hamuti hoiho kia rite te rahi

I muri i te whakarite rauemi, Me whakahanumi kia rite, ka whakaemihia ki nga rarangi roa, ka waiho ranei ki roto i nga awaawa FERMENTATION. Ko te tikanga o mua me nui te waahi me te papa papatahi. A ko te mea whakamutunga e hiahia ana koe ki te hanga i nga awaawa FERMENTATION, e toru nga taiepa.

3.Hurihia nga rauemi i ia wa

Ko te hanga wairākau he a pirau koiora tukanga. Ka huri nga microorganisms i nga mea waro hei matūkai ma te tango i te hāora me te makuku. I te wa ano, ka nui te wera ka puta, ka aukati i te mahi microorganism me te patu huakita whai hua. Ma te huri haere tonu o te puranga wairākau ka nui te hāora mo te FERMENTATION, whakatikahia te pāmahana me te whakakotahi i nga rauemi ki nga waahanga katoa kia rite. Ko te tikanga, ma te hurihanga o te puranga wairākau ka pai nga tikanga mo te FERMENTATION, kia tere ake te wa wairākau me te whakapai ake i te kounga wairākau. Ka mutu te hanga wairākau, ka heke te rahi o te puranga wairākau, ka ngaro te haunga o mua, ka marara, ka mangu te hamuti hoiho. Kātahi, ka taea e koe te whakamahi hei whakatikatika oneone me te tongi mo nga tipu.

SEEC mihini wairākau mo tere wairākau

Ma te huri i nga wa katoa ka pa katoa nga hamuti hoiho ki te hāora, ka taea te whakaiti i te pāmahana me te tango i te makuku. Te whakakapi i nga kaimahi ki te mihini wairākau ka taea te whakapoto i te wa whakangao wairākau me te penapena utu mo te mahi. I konei ka whakaurua e matou nga momo miihini whakawairakau hoiho e toru.

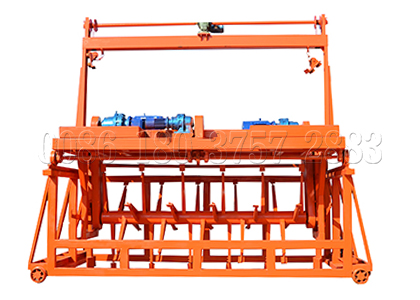

Mīhini wairākau mo te hau hamuti hoiho (20-30 ra’ wā FERMENTATION)

Whai muri i te whakaemi i te hamuti hoiho me te kaitapa ki nga rarangi roa, Ka taea e tetahi taraiwa te whakahaere i te kaitahuri wairākau hau ki te huri i te puranga wairākau. Ko te kaitahuri wairākau toia-whaiaro me te kaihuri wairākau momo ngokingoki no te kaihuri wairākau wairākau.. Ka taea e ratou te hora ki runga i te puranga wairākau. Ka anga whakamua, ka whakakorikori a ratou taputapu huri i te hamuti hoiho ki te whakatikatika i te puranga wairākau. E wha nga wira a te kaitahuri wairākau toha ki a ia ano, he ngawari i te wa e mahi ana. Ko te kaihuri wairākau momo ngokingoki ka mau i te tahuhu ara rapa, e pumau ana i te wa e mahi ana.He aha atu, ka taea e koe te whakakii i a raatau ki te punaha rehu, ka taea te taapiri wai ki te puranga wairākau i nga wa katoa. He waka kei runga i te kaihuri wairākau, ka taea te wehe i te kakara me te wera nui. Ko tenei hoahoa tangata e whakarato ana i te taiao pai mo te kaiwhakahaere. Ka mutu, e rua o nga kaitahuri wairākau e rua na te diesel.

He miihini whakangao wairākau mo te momo haehae hoiho (20-30 ra’ wā FERMENTATION)

I muri i te whakatakoto i te hamuti hoiho ki roto i nga awaawa FERMENTATION, ka neke te kaitao wairākau momo haehae ki runga i nga pakitara whakarara hei huri i te hamuti hoiho. Ko nga taputapu whakakorikori i runga i te kaitahuri wairākau momo haehae ka tino pa ki te hau.. Me tohu noa koe i tetahi tangata hei timata me te kati i te kaitahuri wairākau i runga i te rūnanga whakahaere. Tīmata, kei reira te miihini whakawhiti, ka taea e koe te neke i te momo riaka wairākau hurihanga mai i tetahi riu ki tetahi atu awaawa., Ka taea hoki e koe te kowhiri i te kaihuri wairākau momo wira me te kaihuri wairākau momo pereti mekameka.

Te whakawairakau i te hamuti hoiho ma te wairākau waka (7-10 ra’ wā FERMENTATION)

I roto i te ipu wairākau no ki te mīhini wairākau aunoa, ka taea te whakaoti i te whakawairakau hoiho 7 ki 10 ra. Ko te rōrahi FERmentation mai i te 5m3 ki 150 m3. I muri i te maka i nga mea whakauru ki roto i te wairākau, ka whakahaere aunoa i nga tikanga FERMENTATION ka mutu te mahi wairākau. He rūnanga whakahaere PLC, you can monitor fermentation conditions from it. The stirring apparatus inside the composter will periodically turn the materials, and the air supply system can provide enough oxygen.In addition, there is deodorization system, which can effectively deal with odor and other gases produced by fermentation. When the fermentation finishes, you can get quality horse manure compost from the discharge port. Whai muri i nga ra maha o te whakapumautanga, you can use it directly to soil and plants or for commercial organic fertilizer production.

How to make compost fertilizer production from horse manure?

Horse manure compost fertilizer production is an easy way to make commercial organic fertilizer. In terms of low cost and easy operation, compost fertilizer production line is a popular choice for small horse farm or small organic fertilizer factory. The detailed steps and necessary machines include:

1.Crushing horse manure compost with new type vertical crusher: Crushing process is used for deal with caking or bulks in horse manure compost, so as to guarantee uniformity of fertilizer. SEEC vertical crusher adopts blades and chains to crush caking into small particles.

2.Screening compost with rotary screen machine: Screening process is used for further making uniform compost powder. Rotary screen machine can be designed with two or more screening levels, which can make more uniform and pure fertilizer compost.

Procedures and machines for making commercial Manuru hoiho fertilizer pellets

In addition to horse manure fertilizer powder, you can also produce horse manure fertilizer pellets. Since the fertilizer pellets are convenient for transportation, storage and application, its production process is more complex and stricter.

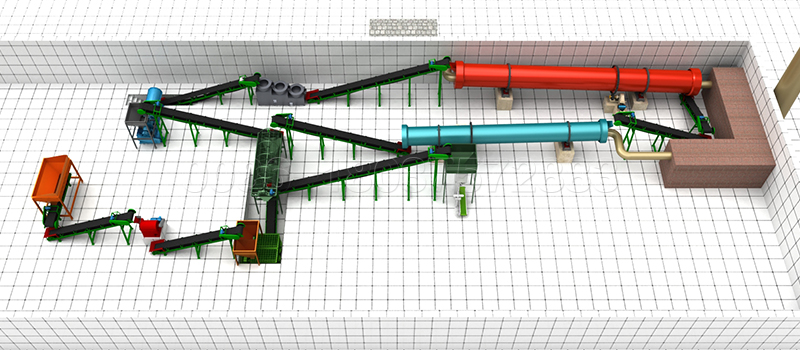

The complete procedures to make granular horse manure fertilizer

Crushing process (eliminate caking and make uniform compost) —Te tukanga tirotiro (select out compost with unqualified size, so as to provide uniform particles for granulation) —[Te whakaranu (add other materials to horse manure compost and mix them evenly, so as to improve fertilizer effect)] —Te tukanga miiharo(make fertilizer pellets by mechanical force and water)—te whakamaroke me te whakamatao (take away extra moisture of fertilizer pellets by hot air and cool them down to ambient temperature)—

—Te tukanga tirotiro (to guarantee the uniform of fertilizer pellets)—[polishing process (in order to make the appearance of fertilizer more beautiful) — coating process (you can coat pellets with functional bacteria, anti-blocking agent and so on)] — te mahi takai (make bagged fertilizer).

Multiple fertilizer pellets making machines for you to choose

We will introduce all machines that may be adopted here, and you can choose and combine different machines for production. All of these machines play different roles in the fertilizer pellets production. And they are suitable for dealing with other manures, penei chicken manure fertilizer making, goat manure compost fertilizer production and so on.

Compost crusher and screening machine

After long-term stack, there must be bulk or caking in the compost pile. Compost crusher is designed for eliminating caking and produce fine and uniform compost. The crushing device inside the compost crusher can well crushed horse manure compost into small particles. There is new type vertical crusher, semi-wet material crusher and hammer crusher (for large scale production) for you to choose. Because granulating process has higher requirements on the uniformity of compost, you had better adopt screening machine to select out smaller or larger compost particles. SEEC rotary screen machine have two or more screening levels, which can meet your different requirements on size of compost powder. Hei taapiri, screening machine can also be used after granulating, which can select out unqualified fertilizer pellets.

Batching machine and mixing machine

Different application objects have different requirements on nutrients. Nō reira, you may need to add some other elements to horse manure to increase its function. The function of batching machine is to continuously provide a certain number of elements for mixing. And you can adjust the parameters of batching machine. I te wa ano, the mixing machine is responsible for mix these materials evenly. And the conveyor belt will send mixed materials to granulator. There are horizontal mixer and disc mixer for you to blend materials evenly. Both of them can blend materials evenly in short time.

Horse manure fertilizer granulator

All SEEC granulators adopt wet granulation.

| SEEC granulator | Features and information |

|---|---|

|

|

|

|

|

|

|

|

|

Rotary drum drying and cooling machines

The standard moisture for final fertilizer pellets product is less than 15%. The moisture of pellets will increase during granulating process, because of the involvement of water. Nō reira, you should adopt rotary drum drying machine to remove extra moisture. I taua wā, the rotary drum cooling machine is used for cooling pellets down to normal temperature, so as to provide convenience for screening and packing. And there are some auxiliary machines, including hot blast furnace for providing hot air and dust collector.

Polishing and Coating machines

Polishing machine can make horse manure fertilizer pellets more beautiful and uniform by centrifugal force generated from high-speed rotation. It is an ideal machine for fertilizer pellets making. Coating machine is used for spray some anti-blocking agent, functional bacteria and sustained-controlled release preparation on the surface of fertilizer pellets. He aha ake, it can also coat compound fertilizer with different colors. In terms of their functions, they are also necessary in large commercial production.

Horse manure pellets packing machine

The horse manure pellets packing equipment includes single-bucket packing scale and double-bucket packing scale. Compared with single-bucket bagging machine, double-bucket packing machine can feeding bags with different amounts of pellets in turn. For example, you can produce 25kg/bag and 50kg/bag horse manure fertilizer at the same time. Single-bucket packing scale is usually suitable for small scale fertilizer production. Both of them can automatically finish feeding, filling and sewing fertilizer bags.

Horse manure high position manipulator palletizing machine with high efficiency

After packing process by fertilizer bagging machine, palletizing machine can help you solve carry problem. It adapts professional servo control system to simplify the manipulator. The control system can set up different palletizing modes according to your needs. That means the number of stacking layers and the number of pallets per layer can be easily controlled by your requirements. Compared with manual palletizing machine, it is harder to collapse and looks neat and beautiful. Hei taapiri, the structure of operation is simple and convenient. Heoi ano, the most important point is that the cost is lower than manual palletizing machine.

SEEC advice for you to make own organic fertilizer plant from horse manure

If you want to build a horse manure fertilizer plant on your farm, or you just a beginner in organic fertilizer industry, we can give you some professional instruction and advice on building organic fertilizer plant. And we will analyze this problem from the following two aspects.

What should you prepare before making fertilizer plant?

- Raw material: It is the first factor that needs your special attention. If you breed horse, you can collect horse manure from your own farm. By building a horse manure fertilizer plant, you not only find a good way to deal with horse manure and barn bedding, but also get extra income. If you do not have direct raw material source, you should collect it from nearby places to save cost.

- Site for building fertilizer plant: For house farm, you can build the fermentation site and production line on the farm. Or you should build a plant that close to raw materials source. Hei taapiri, the ground for building fertilizer plant should be flat and concrete.

- Selection of fertilizer making machines according to requirements on final fertilizer product: The final product and its output decide the selection and preparation of fertilizer production equipment.

Note: If you do not know how to calculate the area of fertilizer plant and the preparation of fertilizer making equipment, you can tell us your conditions and requirements to us. And our engineer will provide you a detailed production design.

Starting an organic fertilizer plant from small scale manure fertilizer production line

For horse farm and beginner, we recommend small scale compost fertilizer production line. I te ringa kotahi, the circle of production is short and efficient (Te whakahiato—crushing—screening —packing), and it occupy less space. I tetahi atu taha, the investment of small-scale production line is low and the application is wide. You can produce commercial fertilizer from all decomposed organic waste available in short time with low cost. Ka mutu, you can directly sell them in nearby places, which is convenient for transportation and application. I roto i tetahi kupu, small scale compost fertilizer production will be your first choice to start organic fertilizer plant. This method is also suitable for fertilizer production from other organic wastes.