Kompos is 'n effektiewe manier om perdemis in organiese bemesting te verander. Deur kompos, parasiete en onkruidsade in die vars perdemis sal doodgemaak word. Na verkryging van kwaliteit perdemis kompos, jy kan dit direk gebruik of kommersiële perdemis kunsmis maak. Jy het twee keuses, perdemis kompos kunsmis produksie en perde mis kunsmis korrels produksie. U kan die gedetailleerde prosedures en nuttige masjiene in die volgende dele vind.

Professionele perdemis afvalbestuursplan vir jou om perdeafval in kunsmis te verander?

’n Behoorlike perdemis-afvalbestuursplan is nodig vir jou om perdemis te hanteer, veral om perdemis in kunsmis te verander. Dit is beskikbaar vir plaasafvalbestuur en kommersiële kunsmisproduksie. Hier, ons sal vir jou 'n professionele en volledige bestuursplan bekendstel, kompos perdemis— die maak van perdemis kompos kunsmis of perde mis kunsmis korrels. Eerstens, jy moet geskikte ruimte voorberei vir perdemiskompos en die daaropvolgende proses van perdemiskompos.

Die oppervlakte vir kompos kan met die formule bereken word: kompos area= uurlikse uitset* werksure* fermentasieperiode/die digtheid van materiaal/hoogte van komposhoop of diepte van gestapelde mis. As jy net perdemis kompos wil maak, werke sal hier verby wees. In terme van kommersiële perdemis kunsmis produksie, jy moet 'n werkswinkel naby fermentasie area maak om perd te plaas misbehandelingsmasjiene.Jy kan perdemis kunsmis poeier en korrels produksie lyn maak of albei van hulle. Besonderhede is soos volg.

Prosedures om perde-afval te kompos

Kompos is die eerste en belangrikste stap tydens die maak van perdemis kunsmis produksie. Vir kwaliteit en suksesvolle kompos, jy behoort te doen:

1.Voorbereidingsmateriaal

Vir vars perdemis, jy moet sy vog aanpas 50% na 60% deur swas vloeibare mis skeier. Ook, jy kan 'n paar hulpmateriaal byvoeg om vog aan te pas, C/N-verhouding en verbeter ventilasie van komposhoop, soos beddegoed, strooi poeier, saagsels, rys dop poeier en so aan.

2.Stapel perdemis in die regte grootte op

Na die voorbereiding van materiaal, jy moet hulle eweredig meng en in lang rye opstapel of in fermentasiegroewe plaas. Eersgenoemde metode benodig groot spasie en plat grond. En laasgenoemde het jou nodig om fermentasiegroewe te bou, wat uit drie mure bestaan.

3.Draai die materiaal gereeld om

Kompos is 'n biologiese ontbinding proses. Mikro-organismes sal organiese stowwe in voedingstowwe omskakel deur suurstof en vog aan te neem. Terselfdertyd, groot hoeveelheid hitte sal produseer, wat mikroörganisme-aktiwiteit kan inhibeer en selfs nuttige bakterieë kan doodmaak. Die gereelde draai van komposhoop kan genoeg suurstof vir fermentasie verskaf, pas temperatuur aan en meng materiaal in alle dele eweredig. Dit wil sê, die draai van komposhoop sal gunstige toestande vir fermentasie bied, om die komposperiode te versnel en die komposkwaliteit te verbeter. Wanneer die kompos klaar is, die volume komposhoop sal verminder, oorspronklike reuk sal verdwyn en die perdemis sal los en swart word. Destyds, jy kan dit as grondverandering en kunsmis vir plante gebruik.

SEEC kompos masjiene vir vinnig kompos

Die gereelde draai kan perdemis ten volle kontak maak met suurstof, wat beide temperatuur kan verlaag en vog kan wegneem. Vervang arbeidsmag met kompos masjiene kan komposperiode grootliks verkort en arbeidskoste bespaar. Hier sal ons drie tipes perdemis-komposmasjiene bekendstel.

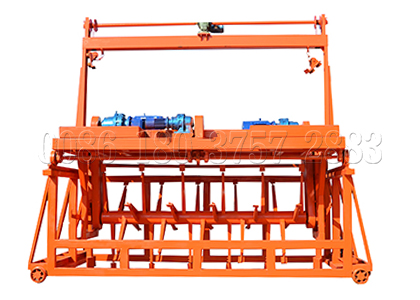

Perdemis windry komposmasjien (20-30 dae se fermentasieperiode)

Nadat perdemis en bulkmiddel in lang rye opgestapel is, een drywer kan die windry-komposdraaier gebruik om die komposhoop om te draai. Beide selfaangedrewe komposdraaier en kruiptipe komposdraaier behoort aan komposwindrydraaier. Hulle kan oor die komposhoop span. Wanneer hulle vorentoe beweeg, hul draaiapparaat sal die perdemis roer om die komposhoop te herrangskik. Die selfaangedrewe komposdraaier het vier wiele, wat buigsaam is tydens werk. Die kruiptipe komposdraaier neem rubberspooronderstel aan, wat bestendig is tydens operasie.Wat meer is, jy kan hulle met spuitstelsel toerus, wat enige tyd water by komposhoop kan voeg. Daar is 'n kajuit op die komposdraaier, wat reuk en hoë temperatuur kan skei. Hierdie gehumaniseerde ontwerp bied 'n goeie omgewing vir operateur. Ten einde laaste, albei die twee komposdraaiers is dieselgedrewe.

Groef tipe perdemis komposmasjien (20-30 dae se fermentasieperiode)

Nadat perdemis in fermentasiegroewe geplaas is, die groef-tipe kompos-tuner sal op die ewewydige mure beweeg om die perdemis te draai. Die roerapparaat op die groeftipe komposdraaier sal die mis ten volle met lug in kontak maak. Jy hoef net een persoon aan te wys om die komposdraaier op die beheerkas te begin en toe te maak. Verder, daar is skofmasjien, wat jou kan help om groeftipe komposdraaier van een groef na 'n ander groef te skuif. As jy grootskaalse mis het om weg te gooi, jy kan ook wieltipe komposdraaier en kettingplaattipe komposdraaier kies.

Fermenteer perdemis deur in vaartuig kompos (7-10 dae se fermentasieperiode)

In vaartuig komposter behoort aan outomatiese komposmasjien, wat perdemis kompos kan voltooi 7 na 10 dae. Sy fermentasievolume wissel van 5m3 na 150 m3. Nadat gemengde materiaal in houer kompos gesit is, dit sal outomaties fermentasietoestande beheer en kompos voltooi. Daar is 'n PLC-beheerkas, jy kan fermentasietoestande daaruit monitor. Die roerapparaat binne die kompos sal die materiaal periodiek omdraai, en die lugtoevoerstelsel kan genoeg suurstof verskaf.Daarbenewens, daar is 'n deodoriseringstelsel, which can effectively deal with odor and other gases produced by fermentation. Wanneer die fermentasie klaar is, you can get quality horse manure compost from the discharge port. Na 'n paar dae se stabilisering, you can use it directly to soil and plants or for commercial organic fertilizer production.

How to make compost fertilizer production from horse manure?

Horse manure compost fertilizer production is an easy way to make commercial organic fertilizer. In terms of low cost and easy operation, compost fertilizer production line is a popular choice for small horse farm or small organic fertilizer factory. The detailed steps and necessary machines include:

1.Crushing horse manure compost with new type vertical crusher: Crushing process is used for deal with caking or bulks in horse manure compost, so as to guarantee uniformity of fertilizer. SEEC vertical crusher adopts blades and chains to crush caking into small particles.

2.Screening compost with rotary screen machine: Screening process is used for further making uniform compost powder. Rotary screen machine can be designed with two or more screening levels, which can make more uniform and pure fertilizer compost.

Procedures and machines for making commercial perdemis kunsmisskorrels

In addition to horse manure fertilizer powder, you can also produce horse manure fertilizer pellets. Since the fertilizer pellets are convenient for transportation, storage and application, its production process is more complex and stricter.

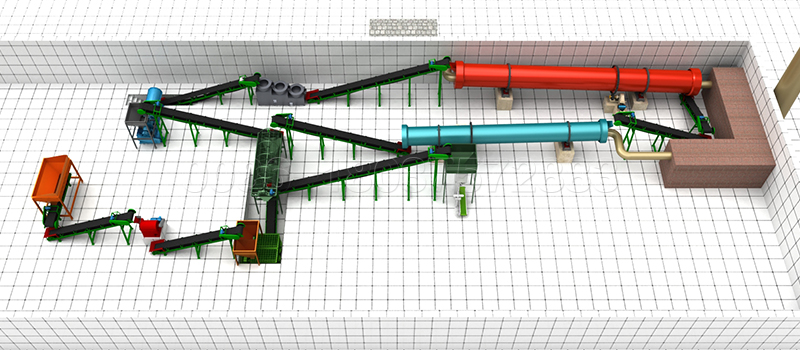

The complete procedures to make granular horse manure fertilizer

Verpletteringsproses (eliminate caking and make uniform compost) —Siftingsproses (select out compost with unqualified size, so as to provide uniform particles for granulation) —[mixing process (add other materials to horse manure compost and mix them evenly, so as to improve fertilizer effect)] —granuleer proses(make fertilizer pellets by mechanical force and water)—droog- en verkoelingsproses (take away extra moisture of fertilizer pellets by hot air and cool them down to ambient temperature)—

—Siftingsproses (to guarantee the uniform of fertilizer pellets)—[polishing process (in order to make the appearance of fertilizer more beautiful) — deklaagproses (you can coat pellets with functional bacteria, anti-blocking agent and so on)] — verpakkingsproses (make bagged fertilizer).

Multiple fertilizer pellets making machines for you to choose

We will introduce all machines that may be adopted here, and you can choose and combine different machines for production. All of these machines play different roles in the fertilizer pellets production. And they are suitable for dealing with other manures, soos chicken manure fertilizer making, goat manure compost fertilizer production en so aan.

Compost crusher and screening machine

After long-term stack, there must be bulk or caking in the compost pile. Compost crusher is designed for eliminating caking and produce fine and uniform compost. The crushing device inside the compost crusher can well crushed horse manure compost into small particles. Daar is 'n nuwe tipe vertikale breker, semi-wet material crusher and hammer crusher (for large scale production) for you to choose. Because granulating process has higher requirements on the uniformity of compost, you had better adopt screening machine to select out smaller or larger compost particles. SEEC rotary screen machine have two or more screening levels, which can meet your different requirements on size of compost powder. Ook, screening machine can also be used after granulating, which can select out unqualified fertilizer pellets.

Batching machine and mixing machine

Different application objects have different requirements on nutrients. Dus, you may need to add some other elements to horse manure to increase its function. The function of batching machine is to continuously provide a certain number of elements for mixing. And you can adjust the parameters of batching machine. Terselfdertyd, the mixing machine is responsible for mix these materials evenly. And the conveyor belt will send mixed materials to granulator. There are horizontal mixer and disc mixer for you to blend materials evenly. Both of them can blend materials evenly in short time.

Horse manure fertilizer granulator

Almal SEEC granulators neem nat granulasie aan.

| SEEC granulator | Features and information |

|---|---|

|

|

|

|

|

|

|

|

|

Rotary Drum Droging en koelmasjiene

The standard moisture for final fertilizer pellets product is less than 15%. The moisture of pellets will increase during granulating process, because of the involvement of water. Dus, you should adopt rotary drum drying machine to remove extra moisture. Intussen, the rotary drum cooling machine is used for cooling pellets down to normal temperature, so as to provide convenience for screening and packing. And there are some auxiliary machines, including hot blast furnace for providing hot air and dust collector.

Polishing and Coating machines

Polishing machine can make horse manure fertilizer pellets more beautiful and uniform by centrifugal force generated from high-speed rotation. It is an ideal machine for fertilizer pellets making. Coating machine is used for spray some anti-blocking agent, functional bacteria and sustained-controlled release preparation on the surface of fertilizer pellets. Wat is meer, it can also coat compound fertilizer with different colors. In terms of their functions, they are also necessary in large commercial production.

Horse manure pellets packing machine

The horse manure pellets packing equipment includes single-bucket packing scale and double-bucket packing scale. Compared with single-bucket bagging machine, double-bucket packing machine can feeding bags with different amounts of pellets in turn. For example, you can produce 25kg/bag and 50kg/bag horse manure fertilizer at the same time. Single-bucket packing scale is usually suitable for small scale fertilizer production. Both of them can automatically finish feeding, filling and sewing fertilizer bags.

Horse manure high position manipulator palletizing machine with high efficiency

After packing process by fertilizer bagging machine, palletizing machine can help you solve carry problem. It adapts professional servo control system to simplify the manipulator. The control system can set up different palletizing modes according to your needs. That means the number of stacking layers and the number of pallets per layer can be easily controlled by your requirements. Compared with manual palletizing machine, it is harder to collapse and looks neat and beautiful. Ook, the structure of operation is simple and convenient. Nietemin, the most important point is that the cost is lower than manual palletizing machine.

SEEC advice for you to make own organic fertilizer plant from horse manure

If you want to build a horse manure fertilizer plant on your farm, or you just a beginner in organic fertilizer industry, we can give you some professional instruction and advice on building organic fertilizer plant. And we will analyze this problem from the following two aspects.

What should you prepare before making fertilizer plant?

- Raw material: It is the first factor that needs your special attention. If you breed horse, you can collect horse manure from your own farm. By building a horse manure fertilizer plant, you not only find a good way to deal with horse manure and barn bedding, but also get extra income. If you do not have direct raw material source, you should collect it from nearby places to save cost.

- Site for building fertilizer plant: For house farm, you can build the fermentation site and production line on the farm. Or you should build a plant that close to raw materials source. Ook, the ground for building fertilizer plant should be flat and concrete.

- Selection of fertilizer making machines according to requirements on final fertilizer product: The final product and its output decide the selection and preparation of fertilizer production equipment.

Noot: If you do not know how to calculate the area of fertilizer plant and the preparation of fertilizer making equipment, you can tell us your conditions and requirements to us. And our engineer will provide you a detailed production design.

Starting an organic fertilizer plant from small scale manure fertilizer production line

For horse farm and beginner, we recommend small scale compost fertilizer production line. Aan die een kant, the circle of production is short and efficient (kompos—verpletterend—vertoning —packing), and it occupy less space. Aan die ander kant, the investment of small-scale production line is low and the application is wide. You can produce commercial fertilizer from all decomposed organic waste available in short time with low cost. Ten einde laaste, you can directly sell them in nearby places, which is convenient for transportation and application. In 'n woord, small scale compost fertilizer production will be your first choice to start organic fertilizer plant. This method is also suitable for fertilizer production from other organic wastes.