In order to deal with cow dung and realize effective utilization, composting will be a good idea. During composting, the microorganisms are responsible for breaking down organic matters into compost. At the same time, heat released from microorganism activity will kill pathogens, weed seeds and eggs. However, how to make cow dung compost? The steps include raw material preparation (manage water content of cow dung, add straw or sawdust to adjust C/N ratio), make compost pile and turn cow dung. After composting, you can use cow dung directly or deeply process it to make commercial organic fertilizer. As professional organic fertilizer equipment manufacturer, SEEC will provide you efficient composting methods for composting cow dung and high-quality cow dung compost production machines.

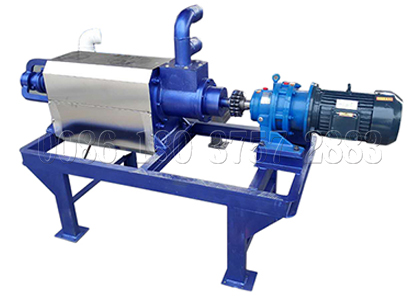

Cow dung dewatering—The first step for making compost from cow dung

Before composting cow dung, you should pay more attention to water content of cow dung. Because improper water content will inhibit composting process and influence quality of compost. As we all know, the water content of fresh manure from cow or cattle are about 80%. But the proper water content for composting is 50% to 60%. In order to control water content better, you can adopt SEEC cow dung dewatering machine to separate extra water from cow dung. What’s more, the dewatered cow dung is loosen and does not have caking, which is conducive to make compost. In addition, the lowest water content of processed manure can achieve 30% to 40%. You can adjust the dewatering degree according to your own requirements.

How does Tonga solid liquid separator machine realize the dewatering of cow dung?

In order to prolong their service life, you should clean the screen in time after operation. In addition, you can also adopt it to deal with chicken manure, manage pig manure and other livestock wastes management.

Efficient methods from SEEC for you to produce high-quality cow dung compost

Preparation of materials

As mentioned above, composting cow dung includes preparation of raw materials and make compost. During composting, the preparations are the same. Besides cow dung, you can add some straw, rice hull, sawdust to adjust water content, C/N ratio and improve air permeability. However, you need to know the straw and rice hull should be crushed into small pieces. Because not crushed straw will create larger gaps in compost pile, which will slow fermentation process. If you want to composting farm wastes from cattle, both the cattle manure and bedding are available.

Three ways for composting cow dung

Cow dung windrow composting: You can stack cow dung in long rows. And you can design the height, width and length of compost pile according to space. The height usually is 0.8-1.m, or you can make compost pile according to model of the compost turner that you purchase.

Composting cow dung in fermentation grooves: You need to build some grooves with at least three walls, where you can place cow dung. The height of cow dung can be 0.8m, 1.0m,1.2m or 1.5m. Compared with windrow composting, groove type composting may occupy more space. But its capacity is larger than that of windrow composting.

Making cow dung compost in the fermentation tank: Fermentation tank belongs to aerobic composting in closed fermentation environment, and it owns higher automatic level. After putting cow dung into it, it can automatically finish composting process.

Turning cow dung regularly with SEEC compost turner

During composting, microorganisms consume water, oxygen and release heat. With the fermentation process, the heat increases and oxygen content decreases, which will inhibit microorganism activity. Thus, you need to turn the compost pile regularly to adjust these conditions. When the temperature of cow dung compost pile reaches 50-60 degree centigrade, you need to use compost turner to turn one time. At the same time, you need to turn the compost pile twice to four times a day during the first week. After the first week, the frequency can reduce to once for every two days. When the odor disappears, temperature of cow dung compost pile maintains in ambient temperature and raw materials become loose, fine and black, it means the finish of the composting process.

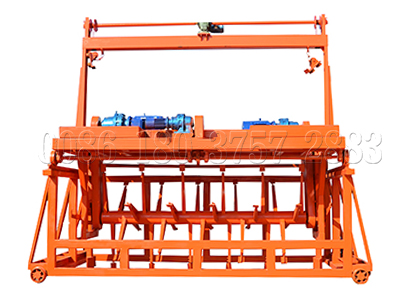

3 kinds of compost turner machines for you to compost cow dung

Easy-to-operate windrow compost turner

There are two types windrow compost turner, crawler type compost turner and moving type compost turner. During working, they will span across the compost pile, and their stirring apparatus will turn the cow dung evenly and thoroughly. After turning, the temperature and oxygen content will achieve favorable level, which is helpful for better compost.

- Crawler type compost turner: It adopts rubber track chassis, which can maintain stability of whole machine during operation. In addition, it has separate driving cab, which can provide a comfortable working environment for worker. There are two hydraulic push plates in the front of the whole machine, which can manage the form of compost pile automatically.

- Moving type compost turner: It is flexible on operation with four wheels. During composting, the blades on stirring shaft will crush larger caking and turn raw materials evenly. And then, the compost pile will become more homogenous on fermentation level.

High-output compost turner for composting in fermentation grooves

Compost turner for composting in fermentation grooves includes groove type, wheel type and chain plate type compost turner. All of them are controlled by electric control cabinets, you just need designate one person to see the working process. In addition, fermentation groove should be made up of concrete, so as to provide strong support to the compost turner and prevent cow dung’s pollution on soil. Groove type compost turner can turn cow dung evenly and crush bulks into small pieces, so as to accelerate composting process and improve compost quality.

Generally speaking, wheel type compost turner is usually used for large scale cow dung composting. Its turning span can achieve 25m. If you have any special requirements on model, function and structure, we can customize it for you. The groove type compost turner has higher working efficiency. Unlike other similar equipment, our groove type compost turner adopts better materials, which has stronger working capacity and longer service life. Meanwhile, chain plate type with high output is suitable for working in deep grooves.

Automatic composting machine with zero waste

SEEC automatic composting machine is also called aerobic fermentation tank. Its volume ranges from 5m3 to 150 m3, but its floor space is just 10 to 30m2. What’s more, it has temperature sensor, which can monitor real-time temperature changes of cow manure in time. There is air supply system, which can guarantee enough oxygen for composting. Above all, it is equipped with biological deodorization system, which can deal with waste air and odor, and release qualified gas. Furthermore, after putting cow manure and other materials into fermentation tank, you just need set parameters on the PLC control system, and will get cow dung compost in 7-10 days. Besides above-mentioned apparatus, there is stirring apparatus, which can regularly turn the materials and send air by holes on it. When the composting finishes, the screw discharge system will send cow manure compost out without stuck.

With the help of SEEC composting machines, how long will it cost to turn cow manure into compost?

According to our experience, composting without any external force will cost three months. However, if you adopt SEEC compost turner regularly stir the cow manure compost pile, the composting period will reduce to 20 to 30 days. In addition, it just cost 7 to 10 days to get cow dung compost by automatic fermentation pot. The reason is that SEEC composting equipment can provide favorable conditions for microorganism activities by adjusting temperature, oxygen content and water content.

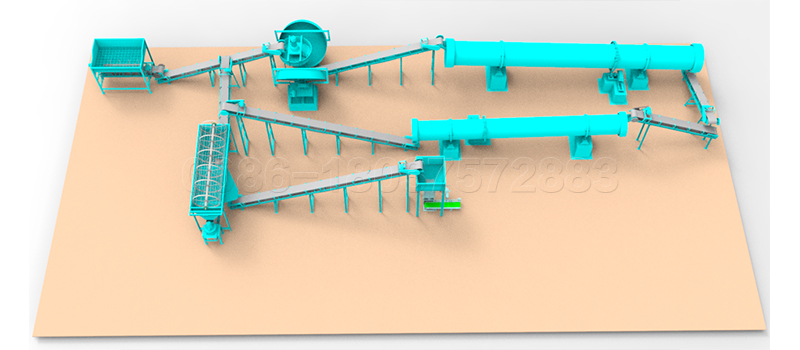

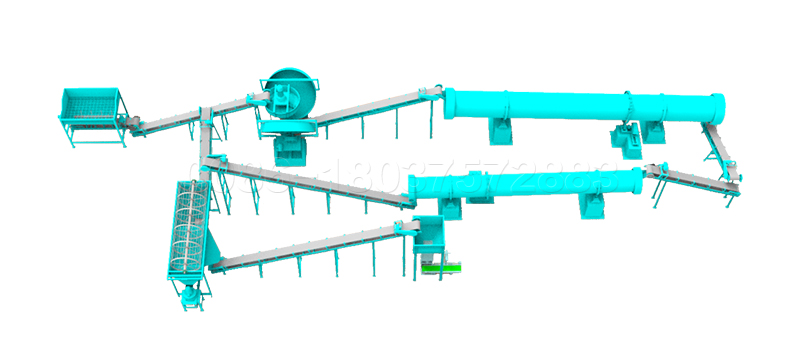

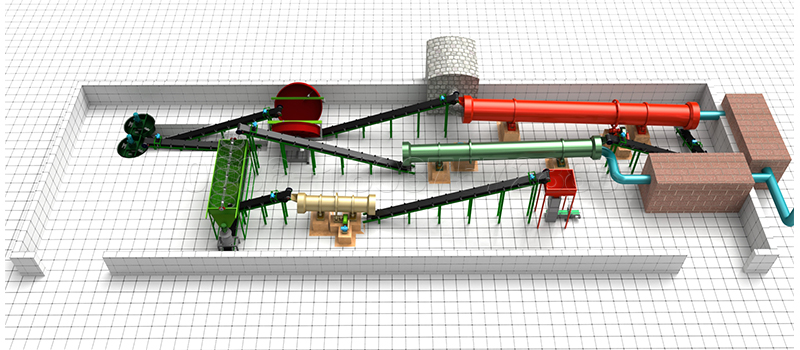

SEEC solutions on commercial cow dung compost production

You can get high-quality cow manure compost after composting. You can adopt it on soil and plants directly. But you can also produce commercial fertilizer, cow dung pellets fertilizer and cow dung powder fertilizer. The making process of cow manure pellets is more complex than that of cow dung powder. The detailed steps of the two solutions are as below.

Making popular compost pellets with cow manure fertilizer pellet machine

In view of convenient application, storage and transportation, cow manure pellets fertilizer is popular in fertilizer industry.

The complete process of converting cow dung compost into pellets includes:

crushing process(eliminate caking)—screening process(select out impurities)—batching process(improve content of nutrients) — mixing process(guarantee uniform fertilizer effect)— granulating process(make cow dung compost pellets)— drying and cooling process(remove extra water content of pellets)—screening process(select out unqualified pellets and send them back for secondary granulation) — packaging process(make bagged cow dung fertilizer).

Among these cow dung processing machines, crushing machine, screening machine, granulator and packaging machine are essential. And other machines are optional, you can select according to your budget and actual requirements.

Producing cow dung powder fertilizer with low cost compost fertilizer making machines

Besides composting equipment, what kinds of cow dung processing machines can SEEC provide?

As mentioned above, you can make bagged cow dung pellets or powder after composting. Here, we will introduce some necessary cow dung processing machines to make commercial cow dung fertilizer.

Cow dung compost shredder machine

Whether you produce cow dung fertilizer pellets or powder, compost shredder machine is necessary. After composting, caking may exist in the compost, so you need to use equipment to make fine compost. There is new type vertical crusher, semi-wet material crusher and hammer crusher for you to choose. All of them can convert compost into fine powder, and they are suitable for different production capacity.

Cattle manure screening machine

On the one hand, in order to guarantee the quality of final products and make preparation for granulation, you should adopt compost screen to select impurities or particles with large diameter. Our rotary screen machine can be customized with different screening levels according to your requirements. On the other hand, you will also use screen machine after granulating. You can separate pellets with unqualified diameters from qualified pellets, so as to improve the quality of bagged cow dung fertilizer.

Cow manure fertilizer pellet machine

Cow manure fertilizer pellet machines usually adopt wet granulation. There is disc granulator, new type organic fertilizer granulator, rotary drum granulator and rotary drum stirring granulator.

- Pan granulator is easy for operation and has high granulation rate.

- New type organic fertilizer granulator makes pellets by mechanical stirring, and the pellets produced have higher hardness.

- Rotary drum granulator can make both compound fertilizer and organic fertilizer pellets, and it is common granulator.

- Rotary drum stirring granulator produce cow dung pellets with the help of stirring force and centrifugal force, therefore the pellets produced by it is more uniform in size and more beautiful in appearance.

Cattle manure fertilizer bagging machine

Making bagged fertilizer is the important step in commercial fertilizer production. SEEC cow dung fertilizer bagging machine has two types. One is for packaging pellets, and the other is for packing fertilizer powder. There is a silo on the packaging machine, which is used for feeding materials, and its smallest volume is 0.3 cubic meters. Besides feeding, it can also finish filling, sealing and sewing. In addition, it has no special requirements on material of bags. You just need designate two or three person to assist.

Vermicomposting, another good way to produce cow dung compost and make high quality organic fertilizer

Besides composting methods mentioned above, you can also apply earth worm to manage cow dung. After dewatering, you can pile up cow dung on concrete ground and put earth worms into it. You should pay attention to that the compost pile shall avoid direct sunlight. The earth worm will eat organic waste, digest it and discharge vermicompost. Vermicompost is a kind of composted and nutrient-rich organic fertilizer. If you want to deep processed vermicompost made from cow dung, you can adopt above production lines (pellets production line and powder production line). In addition, vermicompost is valuable and low-output, so you can add it into cow dung fertilizer as a kind of addition. Here you can adopt SEEC batching machine to adjust the volume of addition.

If you want to make bio-organic fertilizer from cow dung, what kind of proposal can SEEC provide?

Cow dung compost is also a kind of raw materials for making bio organic fertilizer. In order to increase some functions of organic fertilizer, you can add some functional bacterial as well as nutrient elements. The addition of functional bacteria can occur before granulation, in granulation and after granulation (coating process). The bio organic fertilizer production can largely improve the utilization of cow dung compost and is beneficial for soil and plants.