In terms of livestock manure management, using livestock manure as organic fertilizer will be the best choice. And the detailed procedures include composting and subsequent process, which will help you to make quality livestock manure fertilizer. This method is suitable for both manure organic fertilizer factory and various livestock farms (such as manure management for pig farm, horse ranch, dairy farm waste management and so on.). At the same time, you may need to employ some machines during livestock waste disposal. we will show the specific management process and useful machines in the following parts.

The easiest and most efficient method for livestock manure management— aerobic composting

Livestock manure, such as pig manure, horse manure, sheep manure and cow dung, contains a number of nutrient elements. Therefore, you should deal with livestock manure by composting, so as to convert it into nutrient-rich organic fertilizer.During aerobic composting, microorganisms will decompose organic matters in livestock and convert them into nutrients that can be directly absorbed and utilized by plants. Meanwhile, the heat produced from microorganism activity will kill pathogens, weed seeds and eggs, which can prevent soil pollution and plant disease. By composting, you can get useful fertilizer from livestock waste. Thus, aerobic composting is an excellent manure management technique. In SEEC fertilizer machinery, our company manufactures dedicated composting facilities to process the livestock manure into composts, such as horse manure composting machines, turning machines for chicken manure composting, cow dung fertilizer composting facilities, etc.

What should you do to composting livestock manure well?

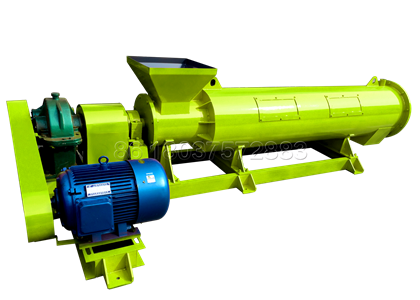

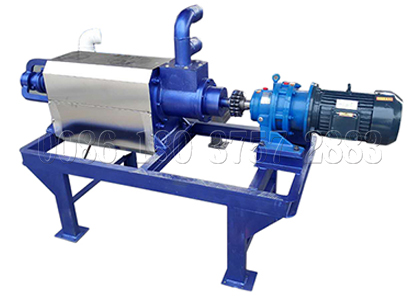

- Materials preparation: You should collect livestock manure and adjust its water content to 50% to 60% by manure separator machine. In addition, you need to add some bulking agents to adjust C/N ratio and increase ventilation of compost pile, such as sawdust, straw powder and so on. And then mix them together.

- Compost pile making: You can place mixed materials in fermentation grooves or pile them in long windrows. The size of fermentation groove can be decided by compost turner you choose. In terms of windrow composting, it is usually 0.6-1.8m tall, 2-3 meters wide and as long as it could possible.

- Regularly turning: The turning of compost pile can adjust oxygen content, release extra temperature and make fermentation more uniform. Because the turning frequency in early stage is high, composting machines are necessary.

What machines can help you during composting livestock waste?

Diesel-powered windrow compost turner

SEEC produces two types windrow compost turners, self-propelled compost turner and crawler type compost turner.

In terms of composting in long rows, windrow compost turner can finish turning in a short time. At the same time, it can rearrange the compost pile during operation. The windrow turning machine is quipped to low diesel emission, which is suitable for working indoors and outdoors.

- High-quality and efficient turning apparatus: The rotating blades can stir organic waste evenly and crush bulks into small pieces, which can shorten composting period.

- Equipped with spray system: Both of them can be equipped with water spraying system (includes water pump, steel pipe, water spray nozzles and water tank), which is convenient for water addition during composting.

- One-person operation: You just need designate one worker to operate this machine, which can greatly save workforce.

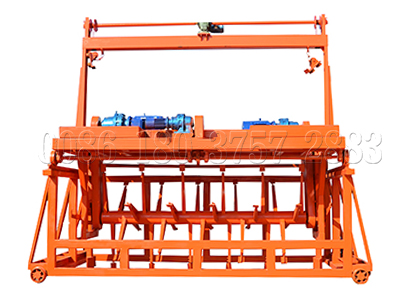

Groove type compost turner for saving workforce and fermentation time

When you make a compost in fermentation grooves, groove type compost turner will be your best assistant.

- It moves on the grooves and can turn the organic waste evenly at a constant speed.

- What’s more, it can work for different grooves with the help of transfer machine.

- Our stirring teeth adopt high-quality materials, which make strong turning capacity and longer service life.

- You can control its working speed by control cabinet, which is easy-to-operate.

Meanwhile, large scale wheel type compost turner and high-output chain plate type compost turner are also available for fermentation grooves. You can choose suitable one, according to the volume of livestock manure, fermentation space and budget.

Fully automatic fermenter for producing quality livestock waste compost

Different with the former two types compost turner, SEEC fermenter has higher automation. You just need to prepare raw martials for composting.

- After putting them into SEEC fully automatic fermenter, you can get quality compost in 7 or 10 days.

- As we all know, you should strictly control the moisture, temperature and oxygen content of the compost pile, so as to make compost successful. With the help of fermenter, you do not worry how to control these factors. You just need to set parameters on the PLC control system. Then, the interior stirring apparatus, temperature sensor, air supply system and deodorization device can separately control the uniform composting, temperature, oxygen content and odor.

- The most important point is that, you need not prepare much space for composting, SEEC automatic composting machine occupies less space than fermentation on the ground does.

Commercial livestock manure management systems provided by SEEC

Besides direct application of composted livestock manure, you can also make commercial organic fertilizer from it. The commercial organic fertilizer from livestock manure is more suitable for sale in market. As professional organic fertilizer machinery supplier, SEEC offer you two commercial livestock manure management system. One is powdery livestock manure fertilizer production, and the other is granular livestock manure fertilizer production.

Easy-to-operate powdery fertilizer production for recycling livestock waste

Powdery fertilizer production is simpler. The complete steps and related equipment are as below:

- Composting process (Compost turner): The involvement of compost turner can accelerate composting period and improve compost quality.

2.Crushing process (New type vertical crusher): New type vertical crusher makes caking and bulk in compost into small particles by rotating blades and chain.

3.Screening process (Rotary screen machine): Rotary screen machine have two or more screening levels. It can select out smaller and larger particles, so as to guarantee the uniformity of compost.

4.Batching and mixing process (Batching machine and disc mixer): Batching machine can help you to accurately add nutrient elements, so as to increase fertilizer effect or functions. And disc mixer is responsible for blending them evenly.

5.Packaging process (powdery fertilizer packaging machine): In this step, packing machine can make bagged compost fertilizer by automatically feeding, weighing, filling and sewing.

Note: The step 4 is optional, you can choose them according to your production requirements.

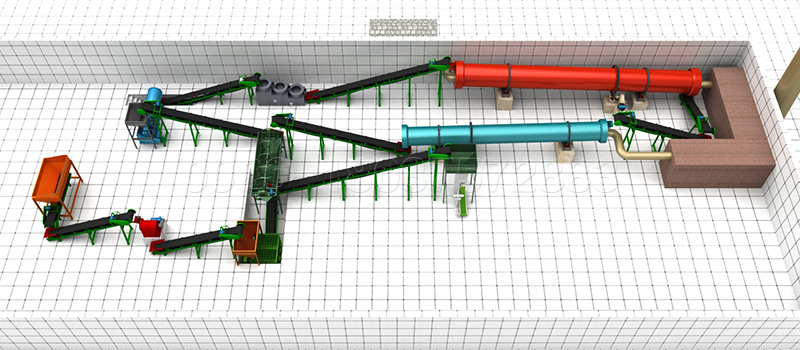

Fertilizer pellets production for livestock manure management

Livestock manure fertilizer production is complex and needs higher investment. Meanwhile, granular organic fertilizer is also popular in fertilizer industry. The complete production procedures include:

- Composting process: Making quality compost from livestock manure.

- Crushing process: Eliminating caking resulted from long-term stacking.

3. Screening process: Guaranteeing uniform of compost by selecting out impurities and particles with unqualified size.

4. Batching and mixing process: For adding other nutrient elements and mixing them evenly.

5. Granulating process: Making granular organic fertilizer pellets by wet granulation.

6. Drying and cooling process: Remove extra water content by high temperature and cool down to normal temperature.

7. Polishing and coating process: Polishing process is used for making pellets spherical and more uniform; you can coat fertilizer pellets with anti-blocking agent, functional bacteria or other materials.

8. Packing process: In this step, you can make bagged organic fertilizer, which is convenient for storage and transportation.

Note: The step 4 and 7 is optional, you can choose them according to your production requirements.

Multiple machine combinations for you to produce commercial fertilizer pellets from livestock manure

Among commercial fertilizer pellets making machines, compost crusher, compost screen and granulator is essential. Because these three processes cannot be finished without machines. According to our experience, we can recommend the following combinations (for reference only):

- New type vertical crusher + rotary screen machine + disc granulator.

- Forklift feeder machine (temporarily store composted livestock manure) + vertical crusher+ rotary screen machine + pan granulator/new type organic fertilizer granulator+ fertilizer pellets packaging machine + mobile belt conveyor (for connecting different processes).

- The forklift feeder + semi-wet material crusher + vibrating screen machine + disc granulator + drying and cooling machine + fertilizer packaging machine + belt conveyor.

- Forklift feeder + vertical crusher + rotary drum screen + batching machine + disc mixer/horizontal mixer + rotary drum stirring granulator + drying and cooling machine + dust collector + fertilizer bagging machine + belt conveyor.

Low-investment manure disposal in livestock farm— livestock manure compost fertilizer production

In terms of livestock manure management on farm, low-cost compost fertilizer production will be the optimal choice. Because livestock farm has fixed manure source, there is no need to worry raw materials. The first thing you should do is composting. You just need to collect livestock manure and pile them together in long rows. At the same time, you should adjust manure moisture, add C rich materials and mix them evenly. With the help of manure composting machine, you can get quality livestock manure compost in 20 or 30 days. After several days’ stabilization, you can use it as fertilizer directly. Or you can adopt compost crusher and compost screen to eliminate caking, select out impurities and make uniform compost fertilizer. Finally, you can employ fertilizer packing machine to make bagged compost fertilizer, which is convenient for storage, transportation and sale. The whole process needs fewer machines and less workforce.