In order to fully utilize goat manure, people often compost goat manure to get harmless compost and apply it to soil and plants. As one of the best animal manures, goat manure can supply nutrients to plants and improve soil structure. Compared with chicken manure and cow dung, the content of nitrogen in goat manure is higher than that in chicken and cow manure. Therefore, you can deal with goat manure by composting. As an organic fertilizer equipment supplier, SEEC can provide you professional composting methods and equipment.

- How to make goat manure compost (composting process and useful composting equipment)?

- Process and machines to make commercial goat manure fertilizer powder and fertilizer pellets.

Composting— A good method for you to use goat manure as fertilizer

This methods is also suitable for other animal manures, such as horse manure disposal, cow dung management and so on. But how to compost goat manure and what should be paid attention to, you will find answers in the following part.

How to compost goat manure?

In terms of composting goat manure, you should focus on moisture (50%-60% is suitable), temperature and oxygen content. To be honest, composting process is microorganism activities. These microorganisms will consume oxygen and water, when they convert organic matters into nutrients. In addition, if the heat they produced is too higher, it will do harm to microorganisms themselves. Therefore, you should strictly control these three factors.

Specific steps for making compost from goat manure

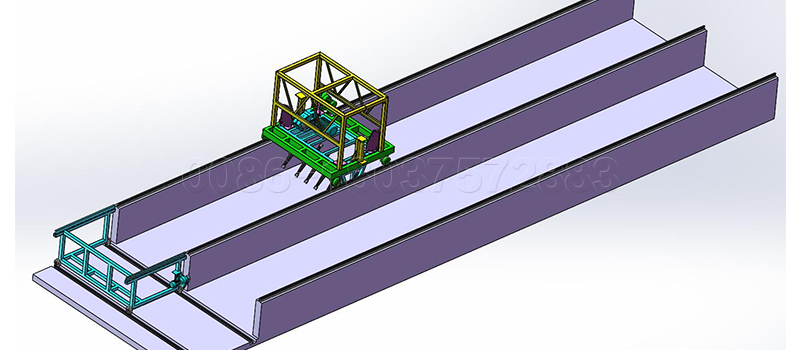

Secondly, you can stack goat manure and auxiliary materials together. You can pile them up in long rows or place them in fermentation grooves. The height, width and length of windrow compost pile are usually 0.8 to 1.5 m, 1.5 to 2 m, and 2 m or more.

For composting in grooves, the height of organic waste should be lower than that of groove.

Finally, you should regularly turn the compost pile, until the fermentation finishes. 2-4 times per day in the first week and 1 time for each two days in the following weeks is enough.

Efficient and economical compost turner for fermentation

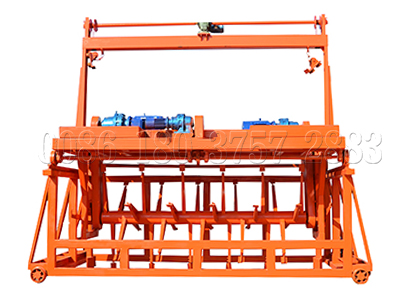

- Goat dung windrow compost turner: Windrow compost turner includes self-propelled compost turner and crawler type compost turner. Both of them just need one person to operate and use diesel oil. The former adopts four wheels, which is flexible and easy for operation. It is very suitable for goat farm manure treatment.

The latter adopts rubber track chassis, which is steady during working. What’s more, their stirring shaft and blades not only can turn compost pile thoroughly, but also crush large caking into pieces.

- Groove type compost turner: It moves on the paralleled walls of groove, while its stirring apparatus turns the goat manure. It is controlled by the electric control cabinet, so one person is enough to monitor its operation. In addition, there is a transfer machine, which can realize one machine for multiple grooves.

Last but not least, it can be equipped with spray device, which can add water in time during turning goat manure.

What should you do to make commercial compost fertilizer with goat manure powder making machines?

Goat manure compost is loose, black and without odor, which is good organic fertilizer. Except for personal use, you can produce bagged goat manure compost for commercial purpose. Here, you may need do the following works and use following goat manure powder making machines.

- Crushing goat manure compost with compost crusher for making fine powder: Due to stack, there must be some caking in fermented goat manure, so you need to eliminate the caking and produce fine powder. Here, SEEC can provide you new type vertical crusher, which can make caking into pieces efficiently.

- Screening goat manure compost with compost screen: In order to guarantee the purity of compost fertilizer and improve its quality, compost screen is necessary. It has different screening levels, so it can guarantee the quality of final fertilizer products.

- Packing goat manure powder with Tongda fertilizer bagging machine: It can automatically finish filling, sewing and packaging.

How to make goat manure fertilizer pellets?

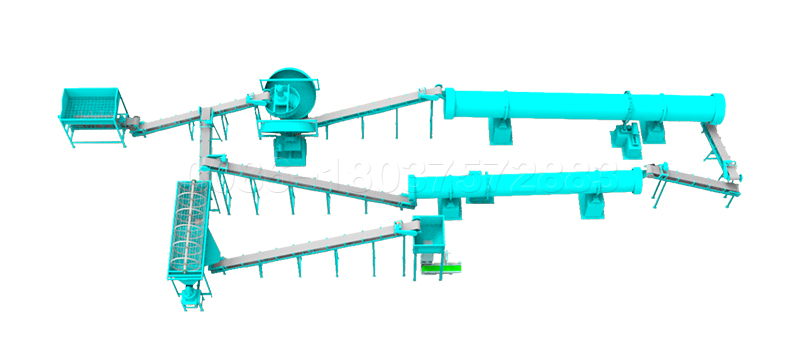

Compost goat manure is just the preliminary process of goat manure management. In addition to make goat manure powder, you can also make goat manure compost into goat dung fertilizer pellets. Fertilizer pellets is more convenient for application, transportation and storage. The complete production process includes crushing process, screening process, granulating process, drying and cooling process, screening process (select out unqualified pellets), coating process and packaging process. Among them, the first two and last processes are same with those of powdery fertilizer production. So, we mainly introduce the following processes:

Goat manure compost crushing process

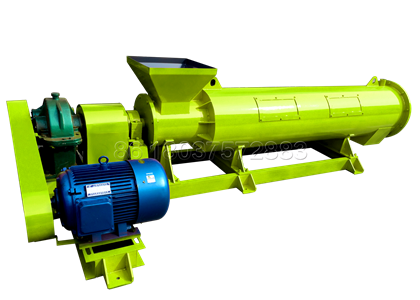

Before granulating, crushing process of goat manure compost is necessary. With the help of the fertilizer crusher, it can completely make the manure compost into powder materials so that we can make a good preparation for mixing process. Through this process, you not only can get high quality compost, but also make full use of making granules. Here, we recommend new type vertical crusher, semi-wet material crusher, hammer crushing machine to you. All of them can help you achieve your purpose.

Goat manure granulating process

After screening, the conveyor belt will send goat manure compost to SEEC granulator. With the help of manure pellet making machines and water, fertilizer powder gradually becomes fertilizer pellets. Here, we recommend new type organic fertilizer granulator to you. It utilizes mechanical stirring force, frictional force and water to make pellets. Therefore, the pellets made by it is harder. Besides new type organic fertilizer granulator, pan granulator, rotary drum stirring granulator are also suitable.

The drying and cooling process

As mentioned above, the wet compost granulation method will increase the moisture of fertilizer pellets. Therefore, you need to remove extra water content of goat manure pellets by rotary drum drying and cooling machine for later screening and packing.(Drier let the goat manure pellet compost ‘s moisture content in a proper rate; cooler will cool the dried compost pellets in a certain temperature for packing and bagging.)The rotary drum drying machine utilizes heat produced by hot blast furnace to dry pellets. The heat usually can achieve 80℃. Then you need to adopt machine to cool the temperature of pellets to ambient temperature and bring vapor on the surface of manure pellets. If you have requirements on the gas released from rotary cooling machine, you can adopt dust collector to deal with it.

Coating manure pellets with rotary coating machine

The purpose of coating goat manure pellets is to inhibit agglomeration among pellets during transportation. What’s more, you can also coat manure pellets with microbial agents to make bio organic fertilizer.

What is the price of the process for making sheep manure compost in our company?

Nowadays how to convert goat manure into organic fertilizer is the biggest problem in eco-fertilizer industry. As we mentioned above, sheep manure composting will be the best method to make fertilizer from goat manure. For sheep agricultural waste managment system, it is very useful for improving our eco-environment and fertilizer industry advance. Meanwhile, in terms of price, compared with other goat manure machine suppliers, it is very reasonable. We can understand the price from 3 aspects.

The first one is that we are manufacturer, not an agent. Therefore, it is required that our origin material is very low with high quality. To some extent, our compost machine can bring good advantages to you. The second reason is that 30 years import and export experience can reduce your time and cost to make a choice. In addition, our professional skills and technology can guarantee our fertilizer equipment be in good condition for a long time. Finally, we can provide special offers which is different in discount time every year, especially on festivals, holidays.

Based on three points, our company will be your best choice whether the price or quality.

How to compost goat manure with windrow composting technology?