Farm waste management plan is mainly used for dispose degradable farm waste, such as poultry manure, livestock manure and bedding (straws). Composting is an efficient and suitable farm waste management practice, which can convert organic waste into useful compost fertilizer. During composting, microorganisms will break down organic matters in farm waste, and convert them into nutrients. At the same time, heat produced from microorganism activity will kill harmful organisms and the volume of farm waste will decrease. In addition, if you can also make farm waste compost into marketable products by deep processing. And the detailed information plans are as below.

SEEC professional instruction on farm waste management plan for different farms

As a professional organic fertilizer equipment manufacturer, we often design organic waste management plan for our customers. We will give them proposal and recommend suitable equipment, according their actual requirements and conditions (budget, raw materials and its volume, production purpose and so on). For the farm waste management, we mainly recommend aerobic composting and fertilizer pellets or powder production line to you. In the following parts, we will introduce it in detail.

Waste management of swine or pig farm to realize nutrient recycling

Generally speaking, pig manure contains much water. If you store pig manure in a cesspool, you need to pump it into solid liquid separator to remove extra water. During composting, carbon is regarded as energy source of microorganism activity and nitrogen-containing materials will be converted to nutrients. The suitable C/N ratio for composting is 30:1, so you can add some crushed straw or sawdust to adjust C/N ratio. And then, you can blend them evenly and pile them in long rows. It is suitable for you to place them under a shed, which can shield rain. Next, you need to turn the compost pile regularly. It is about 2 to 4 times per day in the first week. One time for every two days is enough in the following weeks. If you adopt farm waste composting equipment, the pig manure composting will finish in 20 to 30 days.

Dairy farm cattle waste management plan

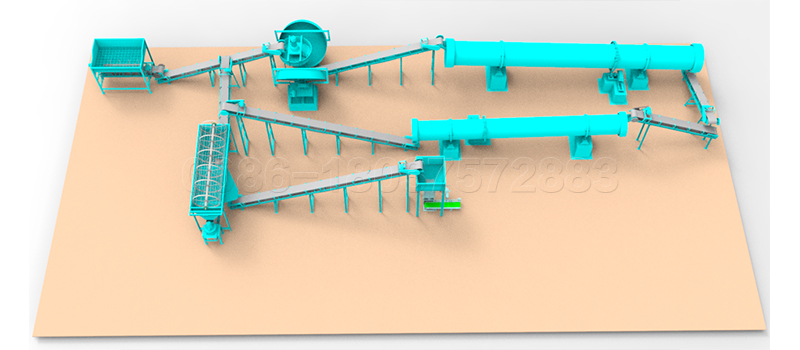

Besides composting cow dung, producing marketable cattle manure fertilizer is also a good dairy farm waste management plan, if you can collect larger amount of cattle waste. The composting process is same with that of pig manure. After composting, you will get nutrient-rich cattle manure compost. On the one hand, you can crush and screen cow dung compost to make fine and pure fertilizer powder, and then you can adopt fertilizer packaging machine to make bagged cattle manure fertilizer.

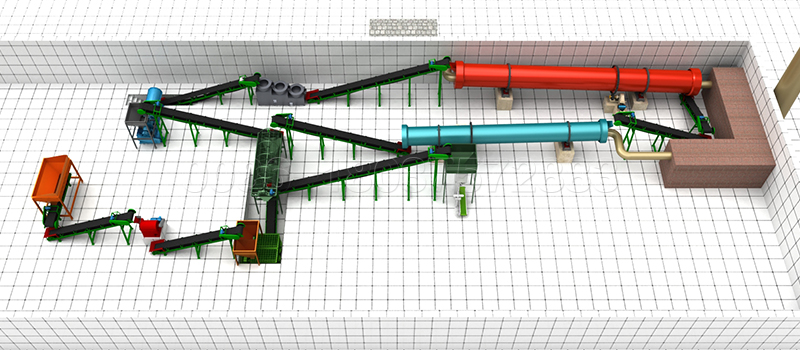

On the other hand, you can make cattle manure compost into fertilizer pellets by granulator. After crushing and screening, cattle manure compost will be sent to granulator. Under the role of mechanical force and water, compost will become uniform pellets. And then you need to dry and cool them, so as take extra moisture away. Finally, you can select out unqualified pellets by screen machine and packaging them.

Waste management in livestock farm

The compostable materials in livestock farm include bedding and livestock manure. You can adopt composting to make them into organic fertilizer, which is beneficial for plants and soil. Before composting, you need to collect and treat them into small pieces as well as dewatering. Here, you can use straw crusher to crush rice hull or straw. Because too large pieces will slow the temperature rise in the compost pile. In addition, you can compost livestock manure both in windrows and fermentation grooves. After composting, you can make fertilizer powder or fertilizer pellets for commercial purpose. If you make compost for personal use, composting is enough. If you want to know more detail design and equipment, you can contact with us.

Poultry farm management system

The volume of poultry litter from poultry usually is not large. Therefore, economical management system for poultry manure is to compost and produce powdery poultry manure fertilizer. For composting, you can build a fermentation groove to place poultry manure and other auxiliaries (sawdust, straw and so on).

You can adopt groove type compost turner to regularly stir the poultry manure, so as to guarantee suitable oxygen content, moisture and temperature. When the composting finishes, you can deeply process it (crushing, screening and packaging). You can adopt semi-wet material crusher to eliminate caking and select out impurities by rotary screen machine. Finally, in order to provide convenience for storage and transportation, you can use fertilizer packing machine to make bagged organic fertilizer. The powdery poultry manure production line needs less space and fewer machines, so it is economical and easy to operate.

What kinds of farm composting methods and equipment are suitable for farm waste management?

Composting is an efficient way to convert farm waste into useful organic fertilizer. The common aerobic composting methods include windrow composting, fermentation in grooves and composting with automatic composting machine. The composting methods and corresponding compost turner are showed below.

Compost windrow tuner for windrow composting

Windrow composting means to pile up farm waste in long rows. The size of compost pile should be larger, which is easy for heating up. Compost windrow turner will span the compost pile during composting. While the compost windrow turner moves forward, its stirring apparatus will turn the farm waste evenly. One driver can operate it. Because it adopts diesel oil as fuel, its working efficiency is higher.

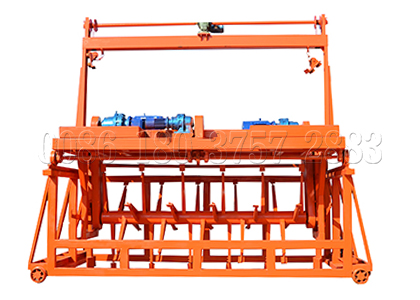

Groove type compost turner for fermentation grooves

Fermentation groove is made up of three walls. The groove type compost turner will move on the two paralleled walls, while turning farm waste stacked in grooves. Compared with windrow composting, groove can accommodate more waste. Unlike windrow compost turner, you can operate groove type compost by electric control cabinet. In addition, both the two types compost turner have spray device, which can adjust water content during turning organic waste.

Automatic composting machine

Automatic composting machine has air supply system, temperature sensor, stirring apparatus, automatic discharge system and biological deodorant equipment. After you put farm waste and straws in it, it will automatically stir waste and control oxygen content, so as to guarantee favorable composting environment. The composting period is usually 7 to 10 days. In terms of odor produced by composting, biological deodorant equipment will deal with it and release clean gas to air. When the fermentation finishes, you can discharge farm waste compost by PLC control system. What’s more, the automatic composting machine occupy less space, so you also can adopt it in farm waste management plan.

SEEC manure pelletizer that suitable for farm waste management

As mentioned above, farm waste fertilizer pellets making is used for commercial fertilizer production. SEEC manure pelletizer has three types, pan granulator, new type organic fertilizer granulator and rotary drum stirring granulator .

Pan granulator with 93% granulation rate : Compost powder become pellets with the rotation of granulating disc. The qualified pellets will enter next process, and the smaller pellets will continue to granulation.

New type organic fertilizer granulator for making harder pellets: By friction and water; The tooth on the stirring shaft will rub wet fertilizer powder into pellets, so the hardness of fertilizer pellets is higher.

- Rotary drum stirring granulator for more perfect pellets: The whole granulating process in this granulator includes spraying water to fertilizer powder, granulating and polishing. Therefore, you can make more uniform and beautiful pellets by this machine.

Besides composting equipment and manure pelletizer, other useful farm waste recycling machines for making organic fertilizer

As we all know, you can make farm waste compost into powdery organic fertilizer and granular organic fertilizer. The powdery farm waste fertilizer production plan includes: composting process—crushing process—screening process—packaging process. However, the granular farm waste fertilizer production plan includes: composting process—crushing process—screening process—granulating process—drying and cooling process—screening process (select out unqualified pellets) —packing process.

| Name of Farm Waste Recycling Machines | Introduction |

|---|---|

|

|

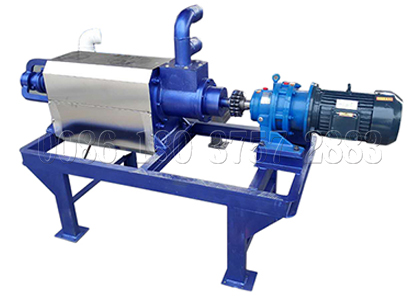

SEEC dewatering machine for rich moisture content farm wastes treatmentGenerally speaking, the water content of animal manure does not fully meet fermentation standard (50% to 60%). If the manure is dry, you can add some water to adjust water content. On the contrary, if the manure is too wet, you should use manure dewatering machine (solid liquid separator machine) to remove extra water. It usually adopts screw extrusion to separate manure and water. After dewatering, you can adopt water from manure to produce biogas. |

|

|

Solid farm waste crushing machineCrushing machine can eliminate caking in the farm waste compost, so as to make preparation for next processes. Whether new type vertical crusher, semi-wet material crusher or hammer crusher, crushing apparatus inside crusher can fully make caking and bulks into small pieces. The crushing level of new type vertical crusher is adjustable. It is our patent product. Semi-wet material crusher is suitable for materials with higher moisture. The hammer crusher is available for large scale production. |

|

|

Compost screen specially designed for high quality organic fertilizer production from farm wastesCompost screen can select out impurities and unqualified products. Therefore, you can adopt it before or after granulating process. Before granulating, it can select out impurities and larger caking in compost, so as to smooth granulating process. When you adopt it after granulating, it can select out unqualified pellets. Conveyor belt will send qualified pellets to packaging machine. However, the unqualified pellets will be sent to crusher for secondary granulation. |

|

|

Fertilizer bagging machine increasing your farm waste fertilizer production treat working performanceThere are two types fertilizer bagging machine, separately for powdery fertilizer and granular fertilizer. There is a silo above the packaging machine, which is responsible for feeding fertilizer. In addition, there is a weighing device, which can accurately control quality of each bag. You also can equip the packaging machine with sewing machine. Then, you just need to designate two persons to monitor the packing process. |

How to start a small-scale organic fertilizer plant in your farm to recycle farm waste?

The small-scale organic fertilizer plant should be placed in a building, where is well ventilated. The composting field should close to farm waste sources. And the production line close to composting field. Because heat and odor will be produced during composting process, there must be well ventilated. The area of plant shall be decided by the quality of materials for composting and equipment you adopted.

If you want to make fertilizer pellets, you may need more machines and larger space, but powdery fertilizer production needs less space and fewer machines. (Detailed machines, please refer to above content).

What kinds of small farm compost systems can SEEC provide you?

As mentioned in the second part, there are three types composting systems, windrow composting, fermentation grooves and automatic compost bin. All of them belong to aerobic composting. The first two methods need large space, you can turn them regularly by compost tuner, which can effectively adjust fermentation conditions. For the fermentation in automatic compost bin, it can finish in 7 to 10 days without any pollution (odor). You can according to your actual requirements to choose suitable farm waste management plan.