In order to fully utilize pig manure and manage pig wastes, you can use pig manure as organic fertilizer by composting. About how to compost pig manure, you can start from pig manure preparation, making compost pile, regular turning to get quality pig manure compost. In addition to composting, you can also make commercial pig manure fertilizer. Furthermore, you may need some machines to accelerate composting process and improve fertilizer production. In the following parts, you can find methods and equipment for composting pig manure.

Composting—a best way for you to use pig manure as organic fertilizer

Composting is a process, where microorganisms digest resoluble organic substance in pig manure and convert it into nutrients. As we all know, the water content of pig manure is higher than manure from other animals. Therefore, it is difficult for you to directly apply fresh pig manure. On the other hand, pig manure may contain pathogenic bacteria, worm eggs and other hazardous substance. The direct application will burn root systems of plant and cause bacterial infections. Hence, we recommend you to deal with pig manure by composting. The microorganism activity during composting will produce heat, which can kill potential pathogens and worm eggs. In addition, it can convert nitrogen, phosphorous and potassium in pig manure to nutrients that can be absorbed by plants. However, how to compost pig manure and what equipment can you adopt? We will make detailed introduction in the following parts.

How to compost pig manure with SEEC manure composting machines?

Composting is a common and efficient way for pig waste management. In order to produce quality pig manure compost, you may need to do the following works:

Collecting pig manure and add auxiliary materials

People usually gather pig manure in a slurry pit. But it is not easy for you collect pig slurry with higher water content. We recommend you dealing with pig slurry with manure separator machine, so as to remove extra water content. The suitable water content for composting is about 55%. As we all know, source of nutrients and content of microorganism is important to make successful compost. Therefore, you can add sawdust, sawdust or straw to adjust C/N ratio and add manure leavening agent to accelerate composting period. During composting, the manure content is 80% to 90%, and auxiliary materials content is 10% to 20%. For each 2.5t pig manure, you can add 1kg manure leavening agents (In order to attenuate leavening agent, you can add 5kg corn flour or rice bran).

Note: Carbon-rich materials include saw powder, manioc waste, straw powder, peanut hull powder, bagasse and rice hull powder.

Making a compost pile with proper size

You can pile up pig manure in long rows, and then spread auxiliary materials (sawdust, attenuated manure leavening agents) on the surface of compost pile. Next, you need to mix them evenly, so as to guarantee uniform fermentation. Too small or too large compost pile is bad for composting, so you should make compost pile with proper size. The height of compost pile usually is 0.8m to 2m, the width is 2m, and the length is 10m to 20m (which depends on your space).

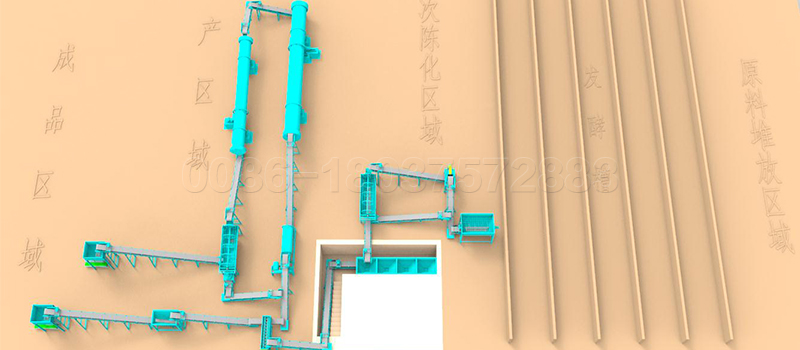

In order to control composting conditions and improve quality of compost, you can draw support from compost turner. Therefore, you can also decide the size of manure heap according to model of pig manure compost turner. On the other hand, you can stack materials for composting in fermentation grooves. The grooves are made up of three walls and usually can contain more manure than windrow composting.

Turning pig manure heap regularly

The ventilation and temperature are key to composting. Microorganisms will consume oxygen to digest organic materials and produce heat. But too much heat will inhibit microbial activity and the production of nutrients. Thus, you should turn the compost pile regularly. When the temperature of compost pile reach 60℃, you should turn them once a day. If the temperature is above 65℃, you should increase the turning frequency (2 or 4 times a day). With the decrease of undecomposed materials, you can turn it one time every two days. With the help of pig manure composting machine, the pig manure can realize full fermentation in short time. In addition to stirring pig manure evenly, the compost turner also can crush caking in compost pile. When pig manure become loose and black, white hypha appears and original odor disappears, you can get quality pig manure compost.

What kinds of pig manure compost machine can you select from SEEC?

According to composting methods, SEEC compost turner falls into three categories, windrow compost turner, groove type compost turner and fully automatic composting machine. All of them can provide favorable conditions for composting, improve compost quality and accelerate composting period.

Windrow compost turner for composting pig manure

SEEC windrow compost turner is suitable for turning pig manure stacked in long rows. It has two types, crawler type compost turner and self-propelled compost turner.

Crawler type compost turner adopts rubber track chassis, which can maintain steady move. The self-propelled compost turner adopts four wheels, which is flexible during operation. Both of them are available for working in the open air, workshop or shed. In addition, their turning apparatus consists of rotating shaft and several rotating knives, which can realize both stirring and crushing. What’s more, you also can equip windrow compost turner with spray device, which can add water to compost pile during turning pig manure.

Both of them have different models, you can select suitable one, according to the volume of pig manure and space you have. It just cost you 20 to 30 days to compost pig waste with the help of windrow compost turner.

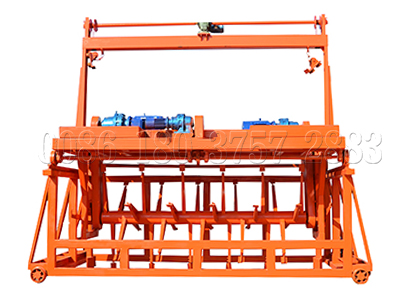

SEEC patent Groove type compost turning machines for your pig manure compost production

Different with windrow composting, you need to build fermentation grooves for groove type fermentation. The fermentation groove usually has three walls, which can contain much pig manure.

The groove type compost turner will move on two paralleled walls during working. At the same time, the turning apparatus will turn and crush pig manure evenly. Generally speaking, the groove type compost turner is equipped with transfer device, which can transport compost turner from one groove to other grooves. In addition, the stirring device of compost turner adopts high quality materials, which has longer service life and strong working capacity.Besides groove type compost turner, wheel type compost turner and chain plate type compost can also turn pig manure stacked in grooves. These two compost turners suitable for large scale pig manure composting. Finally, you can get quality pig manure compost in 20 or 30 days.

SEEC fully automatic composting machine with zero pollution

SEEC fully automatic composting machine can finish composting in 7 to 10 days in general. After putting mixed pig manure into fully automatic composting machine, you just need control composting process by PLC control device.

There are stirring device, air supply system, temperature sensor and biological deodorization. The stirring device will automatically and regularly stir pig manure. The air supply system can send air to pig manure by air vent on the stirring apparatus. The temperature sensor will tell you the real-time temperature in the composting machine. Finally, the biological deodorization will deal with odor and other gas produced during composting, and release them with zero pollution. What’s more, the volume of fermentation pot ranges from 5m3 to 150 m3, which is suitable for different compost production requirements. When the composting is finished, the fermentation bin can send out pig manure compost from discharge opening.

SEEC manure separator machine for you to deal with pig slurry

The higher water content of pig manure increases the difficulty to compost pig manure. Improper management will lead to the failure of composting. Therefore, we recommend SEEC manure separator machine dealing with pig manure. You can collect pig manure in the slurry pit by pump, and the manure separator machine will remove extra water from pig manure by screw extrusion. The minimum water content of output manure can achieve 30% to 40%. You can adopt it for other purposes as well as compost. If you use dehydrated pig manure for compost, you can set the water content to 60%. There are two types manure separator machines, solid-liquid separator and inclined screen for solid liquid separation. The former one is suitable for small scale pig manure management, and its output is 1.5 to 3m3/h. The latter is suitable for large scale pig waste with high water content (90%).

Subsequent process for you to dispose pig waste, after composting

After composting, you can directly apply pig manure to soil and plants. Or you can make commercial pig manure organic fertilizer. There are two methods to make pig manure fertilizer, powdery pig manure fertilizer and pig manure fertilizer pellets.

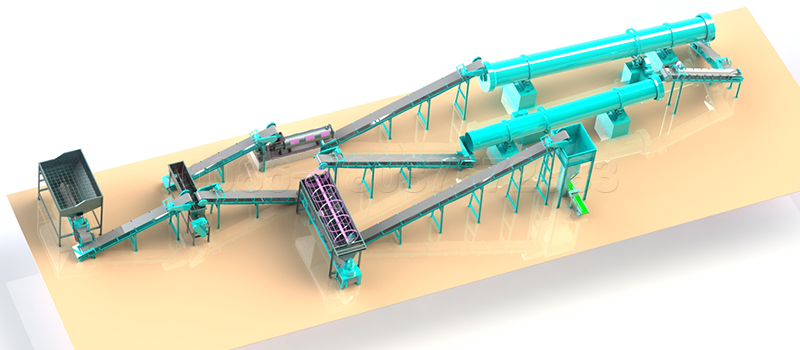

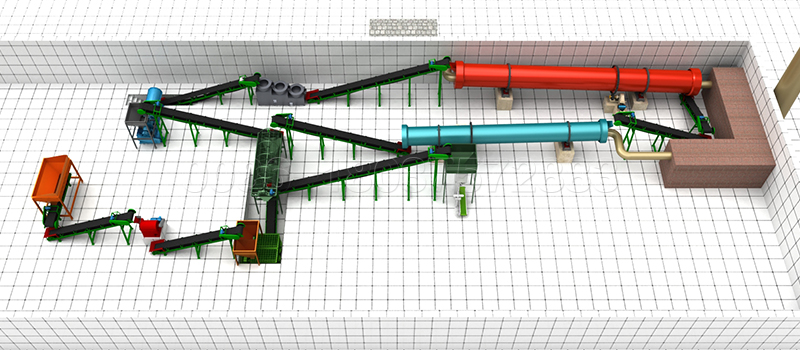

- Pig manure fertilizer powder production includes: crushing process (eliminate caking and make fine compost) — screening process (select out impurities and potential bulk) — packing process (make bagged organic fertilizer).

- Pig manure fertilizer pellets production includes: crushing process — screening process — granulating process (adopt wet granulation) — drying and cooling process (remove extra moisture, up to standard) —screening process (select out unqualified pellets, guarantee the quality of final product) —packing process.

It is more complex than fertilizer powder production. In addition, if you have higher standard on fertilizer pellets, you can also adopt organic fertilizer polishing machine and rotary coating machine to make more beautiful fertilizer pellets. Both of them are suitable for pig farm wastes management.

For quality and efficient pig manure compost production, solutions on temperature, moisture and ventilation control

In terms of successful composting, favorable temperature, moisture and ventilation are essential. You can adjust moisture to 60% by manure separator machine. In addition, you can observe moisture during composting and add proper water to compost pile. For the temperature, you can observe it by thermometer. In the early stage, the temperature will maintain around 50℃. And you start to turn pig manure, when the temperature achieve 60℃. Because the workload is larger in the early stage, you can adopt compost turner to improve working efficiency. What’s more, the compost turner can thoroughly stir the compost pile, the oxygen content in compost pile will correspondingly increase, so as to realize ventilation. Therefore, you can adopt SEEC compost turner to control temperature, moisture (the heat will take moisture away during turning) and ventilation. It will be your best assistant during quality and efficient pig manure compost production.