Making compost is an efficient way to recycle chicken manure. In order to make quality compost, you need pay more attention to composting process. Temperature, C/N ratio, moisture and oxygen content are important factors, which may directly decide the success or failure of fermentation. In addition, regularly turning can improve fermentation conditions, so as to provide favorable environment for microorganism activities. In terms of how to make chicken manure compost and composting equipment selection, you can find detailed and professional information in the following parts.

How to make chicken manure compost efficiently?

During composting, oxygen-consuming bacteria and fungi turn organic matters in chicken manure into nutrients that can be directly absorbed by plants. Therefore, these microorganism activities are the core of chicken manure composting. You should provide favorable conditions for microorganisms, so as to make compost efficiently.

Make preparations for composting

Firstly, collect chicken manure and adjust moisture to suitable level (50% to 60%). Secondly, collect C-rich organic waste (such as sawdust, wood shavings, straw powder and so on), and mix it with chicken manure evenly. Because chicken manure is N-rich materials, the addition of straw power can adjust C/N ratio (25:1). Besides raw materials for composting, you also need to prepare space with suitable size. And a shelter is also necessary, which can prevent compost pile from bad weather.

Build compost pile with proper size

You can stack collected chicken manure in long rows or in fermentation grooves. By contrast, piling up chicken manure in long rows is much easier. You just need to prepare enough space and pay attention to the size of compost pile. Generally speaking, the height of windrows is 0.6m to 1.8m and the width is 2m to 3m. For length of compost pile, it depends on the lengthen of your space for composting. On the other hand, you can build grooves to place chicken manure, which need less space. The fermentation groove is made up of three walls, you can decide the volume of each groove according to that of raw materials. Fermentation groove has good heat preservation, but you may need to adopt compost turner to stir the compost pile regularly. It is not suitable for manual work.

Regularly turn the compost pile for adjust fermentation conditions

After making compost pile, the fermentation process starts. In the earlier stage, the temperature in the compost pile rise quickly. Because there are enough organic materials for microorganism to utilize. When the temperature of compost pile reaches 60 to 70 degree centigrade, turning will be necessary. Generally speaking, the turning frequency in earlier stage is 2 to 3 times a day. In the course of time, organic matters gradually become fewer and fewer, and the microorganism activities become weaker. At this time, you can reduce turning frequency to 1 time for each two days. When the temperature never changes and raw materials become black and loose, it means you complete the fermentation. Before use, you can stack it for several days for stabilization.

Best ways to make your own chicken manure compost

For small scale- or large-scale chicken manure management, there are two methods to make chicken manure compost. One is to make compost pile and the other is to compost chicken manure with earth worms.

Stacking chicken manure in long rows or in fermentation grooves

Firstly, you should prepare enough space for placing chicken manure. You can place them in long windrows directly (as shown in the picture). This method is very easy to handle. Meanwhile, it is convenient for you to regularly turn the compost pile. Or you can build some fermentation grooves to place chicken poop. The fermentation groove usually consists of three walls. Because these grooves usually are deep and long, one groove type compost turner is necessary. Under this circumstance, rails will be laid on paralleled walls, so as to make compost turner move on. Cement ground is better for both windrow composting and fermentation grooves. You can choose on according to your actual requirements.

Making vermicompost from chicken manure

What kinds of compost production machines are necessary during composting chicken manure?

The strict control on fermentation conditions decides the success of composting. In order to make chicken manure compost efficiently, chicken waste composting machine is needed. On the one hand, composting equipment has higher working efficiency, which can save time and workforce. It can deal with large amount of organic waste in a short time. On the other hand, composting equipment can turn the compost pile evenly, so as to guarantee thorough fermentation of raw materials both inside and outside of the compost pile. Here, we recommend three types composting machines.

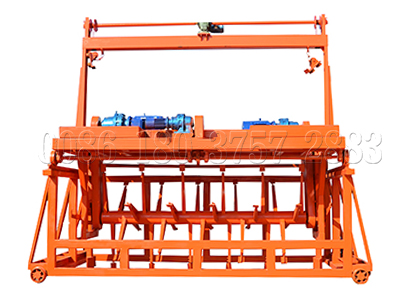

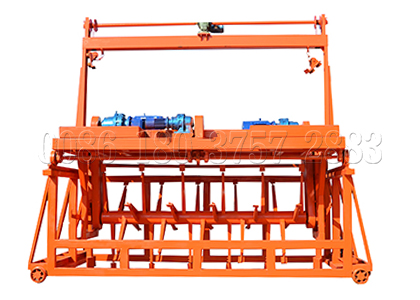

Groove type compost turner

The main parts of groove type compost turner are turning teeth, control cabinet and transfer device. The turning teeth of SEEC compost adopts 16Mn, which is sturdy enough to evenly stir and crush chicken poop. In addition, the rotary shaft can be designed as hydraulic control, which is convenient for adjustment during working. The control cabinet can control the working status of compost turner, you just need one person to monitor it. As for transfer device, it can remove compost turner from one groove to others, so as to save time and improve working efficiency.

Windrow compost turner

Windrow compost turner is available for windrow composting. During working, it spans over the compost pile and uses the blades on the rotary shaft to evenly stir compost pile. SEEC hot-sale windrow compost turner includes crawler type compost turner and self-propelled compost turner.The former adopts rubber track chassis, which is steadier during working. Its turning device that adopts hydraulic control, is easy to operate. The latter adopts four-wheel design. It can stir raw materials to make them mixed evenly and become loose. It is noteworthy that both of them can be equipped with spray device, which can adjust moisture of compost pile by adding water during working.

How to make a commercial chicken manure compost production line?

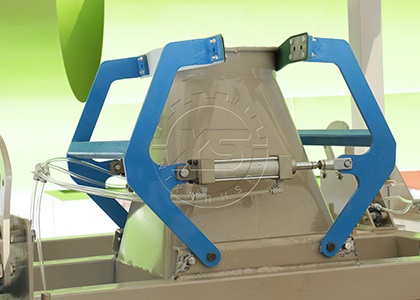

Chicken waste will become soil-like materials after composting. Besides personal use, making commercial compost fertilizer is also a good choice. You can make marketable bagged fertilizer from composted chicken manure. The works needed include: composting process (with compost turner) —crushing process (with vertical crusher to make uniform and fine compost powder) —screening process (with rotary screen machine to select out impurities and potential small caking) —packing process (with powdery fertilizer packing machine to make bagged fertilizer). We SEEC can provide you all relative manure to fertilizer machines with high working efficiency. Chicken manure compost production is featured with low investment and easy operation. If you want to make commercial fertilizer from chicken manure, it will be your prior choice.

How long will it take to compost chicken manure?

As mentioned above, SEEC chicken manure composting equipment can accelerate composting period by adjusting fermentation conditions. According to our test and feedback from our customers, you can finish chicken manure composting with compost turner in 20 to 30 days. In winter, the ambient temperature usually is lower, so fermentation period will be slightly longer. Therefore, composting equipment is necessary for you to make quality compost from chicken manure in a short time.

How about the cost of making chicken manure compost?

The cost calculation of composting chicken manure should include fees for raw materials, space, purchase of equipment. If you want to make commercial chicken manure compost, you may need to invest more money.

Cost of raw materials

If you have a chicken farm where you can get chicken manure directly, you can save the cost on raw materials. If you need to collect and purchase chicken manure from others, we advise you to build your chicken manure fertilizer plant near the raw material origin, so as to save transportation cost.

Cost on site and equipment preparation

The space needed depends on the volume of chicken manure you have. In addition, different equipment used in composting needs different investment. But compared with manually composting, chicken manure composting equipment can save more time and highly improve compost quality. If you want to produce marketable chicken manure fertilizer, you need to prepare more space and consider purchasing more equipment. If you have no idea, our engineer can provide your detailed chicken manure compost production plan. What needs you to do is provide us your requirements and budget.