Pig manure management is a serious problem for pig farm or some manure composting factories. In view of excellent nutrient content in pig manure, composting is the most suitable way to deal with pig manure. In addition to composting, pig manure compost fertilizer production is also available for both pig farm and larger organic fertilizer factory.

Why pig manure management is important for you?

Pig manure contains much water, which is usually stored in the slurry pit. Because of unpleasant smell and its attraction to flies, the long-time stacking of pig manure will cause pollution for surrounding environment and residents. On the other hand, pig manure contains much nutrient elements, such as nitrogen, phosphorous and potassium. Therefore, it can be used as good fertilizer for soil and plants. You can convert it to organic fertilizer by composting and produce commercial pig manure fertilizer. In this way, you can dispose pig waste efficiently and decrease your own fertilizer cost or make more profits.

In terms of pig farm waste management, what solutions can SEEC provide you?

Pig manure management on the pig farm can start from composting or a small-scale compost fertilizer production line. If you just want to convert pig manure into compost for personal use, composting is enough. The small-scale compost fertilizer production is suitable for commercial pig manure compost production. And you can sell them to other people or in organic fertilizer markets. The detailed steps include:

Windrow composting process

Windrow composting is an easy and fast way to compost pig manure. You just need to collect pig manure and pile it in windrows with auxiliary materials (sawdust and straw powder, etc.).

Because pig manure belongs to nitrogen-rich material. You need to add some carbon-rich materials (pin shaving, hay and straw from bedding) to maintain C/N ratio (25:1/30:1). Then you need to mix them evenly, so as to guarantee compost quality. Here, you can adopt windrow compost turner, whose stirring apparatus can mix these materials evenly, and turn the compost pile regularly to create favorable fermentation conditions. In the early stage of composting, you may need turn the compost 1 or 3 times per day. Two weeks later, you can turn it 1 time every two days. The turning of compost pile will redistribute moisture, move less degraded materials on the surface to inside of pile and release extra heat.

Crushing process

The purpose of this step is to produce uniform and fine powder. When the fermentation finishes, the water content of pig manure compost is 25% to 30%. The size of compost may be a little big, and caking may exist because of long-time stack. Therefore, you need to crush pig manure compost after fermentation, which can also provide convenience for sieving process. Both SEEC new type vertical crusher and semi-wet material crusher are available.

Screening process

Sieving process is to ensure the purity and uniformity of pig manure compost. Because organic fertilizer screening machine not only can select out impurities, but also separate larger particles. Here, we recommend rotary screen machine, whose screening levels can be customized.

Packing process

In packaging process, you can make bagged pig manure fertilizer. Because bagged organic fertilizer is convenient for use, storage and transportation. Here, you can fill and seal fertilizer bags manually. Or you can adopt automatic packing machine, which can pack pig manure fertilizer in different weights (25kg/50kg).

Pig waste disposal system for you to convert pig manure into useful fertilizer

As we all know, convert pig manure into useful fertilizer is a good way to recycle pig manure. According to the production purpose (individual use or commercial production), we can provide you three disposal systems for pig manure management.

Pig manure compost production

This system is for personal use. You just need to compost pig manure. Then, you can directly apply it to your land or plants. It is the easiest and most cost-saving method. And if you want to make quick compost, one windrow compost turner is enough.

Bagged pig manure compost fertilizer production

Pig manure compost fertilizer means powdery pig manure fertilizer. Its production includes composting process, crushing process, screening process and packing process. Among them, compost turner and compost crusher are necessary, and you can finish other processes with workers.

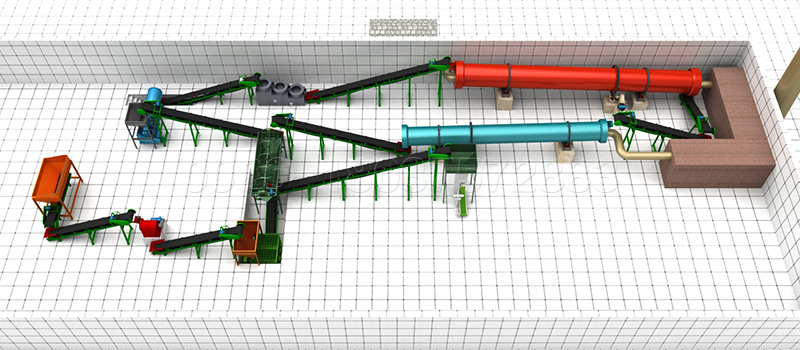

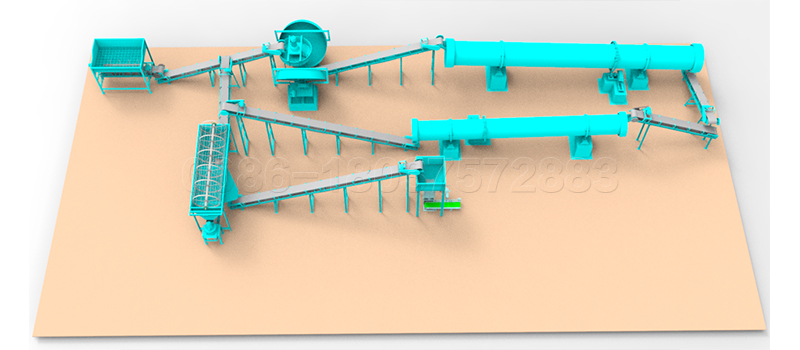

Pig manure fertilizer pellets production

It is more complex than compost fertilizer production. The complete production process is: composting process—crushing process—screening process—granulating process—drying and cooling process—screening process– packing process. You can adopt different product combination to produce pig manure pellets production, such as compost crusher + compost screen+ pig manure fertilizer granulator+ drying and cooling equipment+ packaging machine; compost crusher + rotary drum screen + pan granulator + packaging, etc. You can freely choose any machine, according to your actual conditions (budget, space, requirements on final product).

If you want to turn pig manure into fertilizer, what machines can help you and improve efficiency?

As one of economical method for pig manure management, making organic fertilizer from pig manure is an excellent choice. In order to produce high quality pig manure fertilizer and improve disposal efficiency, you can get help from manure fertilizer making machines. The previous part tells us three pig waste system and detailed process. Here, we will introduce you corresponding machines.

Self-propelled compost turner and crawler type compost turner for composting in pig manure management

Furthermore, we can equip some auxiliary facilities for you, such as automatic sprinkling device. Finally, they are featured with low investment, low consumption and high production capacity.

Compost crusher and rotary screen machine for making uniform pig manure compost

Whether you want to make compost fertilizer or fertilizer pellets, you need to guarantee the uniformity of pig manure compost. Here, you may need two machines, new type vertical crusher and rotary screen machine. The former utilizes chains and blades to crush caking and larger particles to ideal requirements. The rotary screen machine has different screening level, so that it can separate too small and too large particles out, so as to guarantee the uniformity of pig manure compost.

SEEC manure granulator for making organic fertilizer pellets from composted pig manure

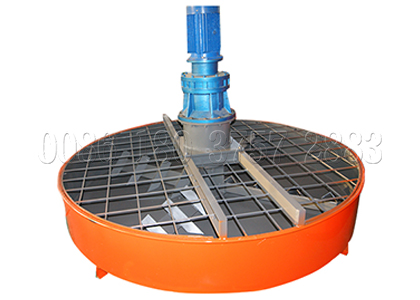

There are three types organic fertilizer granulator, which is available for making pig manure fertilizer pellets, disc granulator, new type pig manure fertilizer granulator and rotary drum stirring granulator. All them adopt wet granulation, and make fertilizer pellets by mechanical force and water. Disc granulator is most common granulator, which is low cost and easy to operate. New type pig manure fertilizer granulator makes fertilizer granules by mechanical stirring force, and its granulation rate can achieve 97%. The structure and function of rotary drum stirring granulator are more compact and stronger than the former two granulators. The pellets made by it is more beautiful and have higher hardness. You can choose suitable one, according to your actual requirements.

Rotary drum drying and cooling machines

Because mentioned granulator adopts wet granulation, you need to remove extra moisture to achieve standard moisture (below 15%). SEEC rotary drum drying and cooling machines can help you. The drying machine take away extra moisture by heating. Then, the cooling machine will cool these pellets into ambient temperature, which is convenient for next process. Here you can build a hot blast furnace to provide heat for drying and dust collector to collect dust produced during drying and cooling. In addition, you can use agricultural waste pellet fuel, coal or gas as the fuel to provide heat.

Automatic fertilizer packing machine for producing bagged pig manure fertilizer

For commercial production of pig manure fertilizer, packing is essential. In order to improve packing efficiency during pig manure management, we design two types fertilizer bagging machine, separately for compost fertilizer and fertilizer pellets. According to weighing method, it includes no-bucket (weighing when filling, which is a little slow) and bucket (filling after weighing, which is quicker) packaging machines. According to working efficiency, it includes single-bucket and double-bucket (which can fill bags with different scales at the same time). And according to packaging scale, it includes 25kg/bag, 50 kg/ bag and 1 ton/bag. In addition to pack organic fertilizer, it also suitable for grain, compound fertilizer and other industries.

What kinds of small pig manure fertilizer machines can you purchase from SEEC?

For small farm or beginner in organic fertilizer industry, we recommend small scale pig manure fertilizer production. All of our organic fertilizer making machines have small size. In addition, if you have any special requirements, we can design pig manure management plan and customize equipment for you. And the small-scale pig manure fertilizer machines and their parameters are as below:

| Machine name | Model | Capacity (t/h) | Size(mm) |

|---|---|---|---|

| Semi-wet material crusher | SEECFLF-600 | 1-1.5 | 1200*1350*900 |

| Disc mixer | SEECPJ | 2-4 | 1600*1600*1600 |

| New type pig manure fertilizer granulator | SEECJZ-600 | 1-1.5 | 4100*1600*1150 |

| Small scale pan granulator | SEECYZ-1500 | 0.5-0.8 | 1760*1500*1950 |

| Rotary screen machine | SEECGS-1020 | 1-2 | Accept cutomization |

SEEC manure separator machine for pig slurry disposal

The high water-content makes pig manure management become more difficult. Therefore, how to remove extra liquid from pig manure? SEEC manure separator can be you best choice. This manure separator utilizes screw extrusion to separate extra liquid. The dewatered pig manure will come out from one end of the machine.

At the same time, the liquid will flow out from the mesh on the cylindrical screen and discharge by pipe. The minimum moisture of dehydrated pig manure can achieve 30% to 40%. You can use it for making organic fertilizer or fish food. In addition, this separator has strong decontamination ability, which can effectively prevent clogging and is easy to clean. What’s more, if you have much pig manure with higher water content (about 90%), you can also adopt SEEC inclined screen solid liquid separator. This kind of separator is featured with high output, easy operation and high efficiency. Like pig manure management, this separator is also suitable for dealing with other livestock manures, such as horse manure management and cow dung treatment.

How can you make special organic fertilizer from pig manure—bio organic fertilizer and vermicompost?

Bio organic fertilizer making for pig manure management

Composted pig manure belongs to quality organic fertilizer, which is nutrient-rich and has no adverse effect to soil. On this basis, you can also make bio organic fertilizer from pig manure. After crushing, you can add functional bacteria by batching machine and blend them evenly. You can finish this operation manually. Or you can adopt SEEC batching machine and fertilizer mixer machine. For large scale bio organic fertilizer production and bio organic fertilizer pellets production, batching machine and fertilizer mixer are essential, which can improve working efficiency and guarantee fertilizer quality. Or you can add functional bacteria by pellets coating machine after granulating.

Vericomposting for pig manure disposal

In addition, you can make vermicompost from pig manure as a method for pig manure management. You can pile up pig manure and straw together, and put earthworms into it. These earth worm will convert pig manure into excellent fertilizer by digestion. As we all know, vermicompost is a kind of valuable organic fertilizer. When pig manure becomes vermicompost, you can make it into compost fertilizer or fertilizer pellets according to above mentioned process. As for the detailed layout, you can refer to this picture (If you have other requirements or problems, you can contact us).

When composting pig manure, you need to pay special attention to three factors

The composting process is the first step in pig manure disposal. Due to its influence on final quality of fertilizer, it is also the most key step. Thus, you must pay more attention to various indicators. Among them, you should focus on moisture, temperature and oxygen content. Meanwhile, this point is also important during dealing with other livestock manures.

Moisture control

Before composting, you should adjust water content of pig manure to 50% to 60%. You can add straw powder or sawdust, which has strong water absorption. Or you can use SEEC solid liquid separator to remove extra water. Because too wet will cause bad ventilation. Too dry will slow heating of compost pile. During composting, you can also sprinkle water according to actual conditions.

Temperature control

You should observe the temperature of compost pile by thermometer. You should turn the compost pile when the temperature reaches 50℃,. Because too higher temperature (above 65℃) will kill good bacteria and microorganism. In the first week, you can turn the compost frequently, 2 to 3 times a day. During the later period of fermentation, you can reduce to 1 time every two days. Because the organic materials nearly run out in the final part. You can adopt compost turner, which can evenly blend outer pig manure and pig manure inside the compost pile.

Oxygen content control

Microorganism digest or decompose organic matters in pig manure while consuming oxygen. When the oxygen is deficient, the microorganism activity will slow. Therefore, you should ensure the ventilation of compost pile. With the help of turning of compost turner, pig manure can fully contact with air. At the same time, the addition of air can also decrease the temperature of compost pile.