Chicken manure pellet machine is an important equipment to produce commercial chicken manure fertilizer pellets. In view of its nutrient elements, chicken manure is a kind of good fertilizer. After composting, you can make granular chicken manure fertilizer for commercial purpose. In addition, organic chicken fertilizer pellets are more convenient for transportation, application and storage. After entering soil, fertilizer pellets not only can provide nutrients to plants, but improve soil aggregates structure and microorganism content. Therefore, granular chicken manure fertilizer will be one of your choices to make organic fertilizer products. As a professional manure to fertilizer equipment supplier, SEEC manufactures four kinds of granulators, disc granulator, new type chicken manure fertilizer granulator, rotary drum granulator and organic waste fertilizer granulator. In the following parts, we will introduce their features and working process in detail.

How to make granulated organic fertilizer from composted chicken manure?

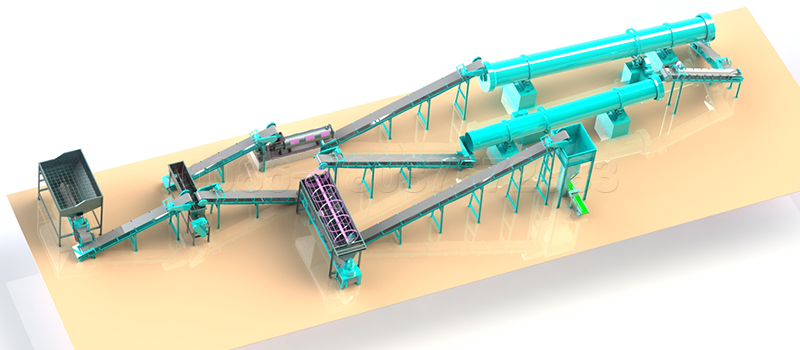

The granulation process is to make chicken manure compost into spherical fertilizer pellets. Finer and more uniform the compost is, more beautiful and uniform pellets produced are. Therefore, you should deal with chicken manure compost before granulating. Firstly, you should adopt compost crusher to eliminate potential caking and larger bulks. Then, you need to use compost screen to select out impurities and unqualified powder, so as to provide quality chicken poop compost for granulation process. Next, the chicken manure pellet machine will make compost into pellets with the help of atomized water and mechanical force. You can get granulated chicken manure fertilizer in this step. Finally, you may need to dry and cool fertilizer pellets, select out unqualified fertilizer pellets and pack quality chicken litter fertilizer pellets.

Multiple efficient manure pellet machines for you to make organic chicken manure pellets

Organic fertilizer pelletizer is the most important equipment in commercial chicken manure fertilizer production. SEEC recommend the following four types granulator. Even though they are different in structure and working principle, all of them have good performance in granulation. At the same time, they are also available for poultry manure fertilizer pellets production.

Easy-to-operate disc granulator with 93% granulation rate

Disc granulator has an open granulation environment, so you can observe the granulation process in real time. Thus, you can adjust the inclination of granulating disc to make fertilizer pellets with needed size. In addition, the back of granulating disc adopts several radiation steel plates, which makes the whole machine sturdy and durable. It also has a cleaning blade, which can efficiently prevent the material from sticking to the bottom. In addition, you can also equip pan granulator with spray device, which can adjust moisture of chicken manure compost to make more uniform pellets. During granulation, composted chicken manure enters the pan pelletizer by conveyor belt. Under the role of gravity, centrifugal force and atomized water, powdery material gradually become spherical pellets. You can control the size of fertilizer pellets by adjusting inclination and rotating speed of granulating disc.

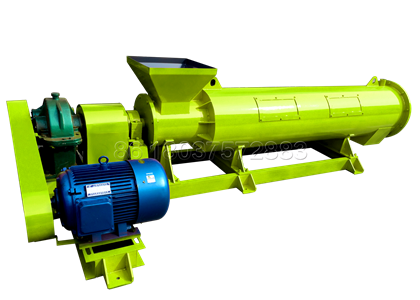

Newly designed chicken manure fertilizer granulator

Unlike disc granulator, new type chicken manure pellet machine finishes mix, granulation, balling and densification of chicken dung fertilizer in a closed environment. It is also called stirring tooth granulator, whose granulation rate can achieve 97%. Its main parts of include main body (made up of seamless steel tube), rotary shaft with spiral vane and stirring teeth and drive part. After entering the granulator from feed inlet, chicken manure compost will be pushed forward by the stirring teeth. At the same time, the manure powder will become pellets, because of the extrusion between stirring teeth and inner wall of main body. Therefore, the pellets produced is harder than that made by pan granulator. It is worth noting that there are three small windows on the main body. This design provides convenience for the maintenance and replacement of stirring teeth.

Note: The head of stirring tooth adopts alloy material, which has good wear ability. And its service life usually is one year.

Rotary drum granulator for making bio-organic fertilizer from chicken manure

Rotary drum granulator can be used in both organic fertilizer and compound fertilizer production. Here, you can regard it as an assistant during bio-organic fertilizer production. Lining with some rubber plate or stainless-steel plate, the compost is not easy to stick to rotary drum. Equipping rotary drum granulator with spray device is alternative. The moisture of raw materials for fertilizer granulation is 25% to 30%. If your materials are too dry, you can install a spray device to increase moisture by add required amount of water. The water addition occurs before granulation, so the length of spray device should not be more than 1/3 length of rotary drum. The chicken manure compost enters from one end, and fertilizer pellets come out from the other end. And the powdery material agglomerates into small particles by centrifugal force. For making bio-organic fertilizer, you can add functional bacteria before granulation by batching system.

Organic waste fertilizer granulator for making pellets with higher hardness

SEEC organic waste fertilizer granulator is also called rotary drum stirring granulator. It is the combination of rotary drum granulator and new type granulator. During granulation, its main body and interior rotary shaft will rotate oppositely. In this way, the centrifugal force and stirring force will make pellets with uniform size and more beautiful appearance. At the same time, the chicken manure fertilizer pellets have much higher hardness. Therefore, these pellets can suffer more pressure in storage and transportation. This machine finishes mixing and granulating compost, and polishing fertilizer pellets.

Besides fertilizer pelletizer, what are the complete granulation system and necessary auxiliary machines?

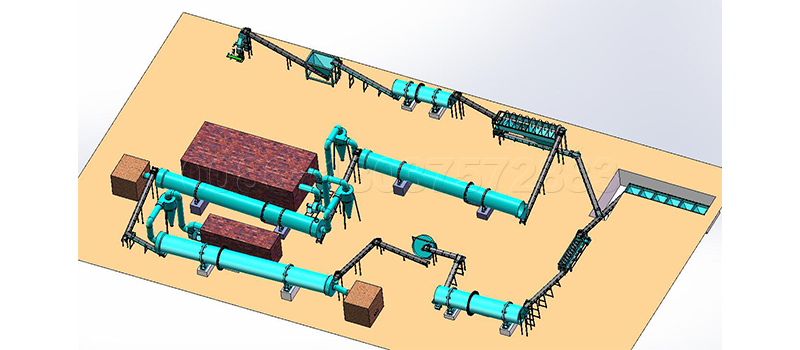

Besides granulation, there are other necessary works. Before granulation, you need to prepare quality and uniform chicken manure compost. Meanwhile, you need to deeply process chicken manure fertilizer pellets after granulation. The complete granulation system and related machines include: Prepare composted chicken manure (compost turner)—Crushing process (compost crusher for getting uniform compost)—Screening process (compost screen for selecting out larger particles and impurities)—Batching process (batching machine for adding other necessary nutrient elements to increase fertilizer effect)—Mixing process (horizontal mixer for blend chicken manure compost and additive evenly)—Granulating process—Drying and cooling process (Rotary drum drying and cooling machine for decrease moisture of pellets to 10%)—Screening process (rotary screen machine for selecting out oversized and undersized pellets and guaranteeing the uniform of final product)—Packing process (fertilizer pellets bagging machine for produce commercial bagged fertilizer).

Note:

1. Batching process and mixing process are optional. 2. We also provide forklift feeder (guarantee the continuous supply of raw materials), storage bin (you can adopt it before packing process), conveyor belt and dust collector.

How do SEEC chicken manure pellet machines make granular fertilizer with uniform size and beautiful appearance?

All of SEEC manure pellet machines adopt wet granulation. The moisture of raw materials before granulation is 25% to 30%. Therefore, adjusting moisture before granulation is necessary. In terms of this point, all of our manure pellet machine can be equipped with spray device, which can provide you great convenience. In addition, you can produce fertilizer pellets with different sizes by adjusting the fineness of pulverization and the rotating speed of equipment. The drive part (electrical machine and reduction gear) provides power for the operation of machine. Compact structure provides favorable granulation environment. Under the coordination of the various parts, SEEC fertilizer pellet making machines can produce quality granular chicken manure fertilizer for you.

SEEC small scale fertilizer pellet making machine for producing chicken manure pellets

For small scale fertilizer pellets production, we SEEC can also provide fertilizer pellet machine with smaller capacity. The minimum production of SEEC small scale chicken manure pelleting equipment is 0.5 ton/h. This small-scale granulator is featured with easy operation, low cost and high granulation rate. Besides small-scale fertilizer production, you can also adopt it for trial production or in laboratory.

Model:

- SEECYZ-1500 Capacity: 0.5-0.8t/h

- SEECYZ-1800 Capacity: 0.8-1.2t/h

- SEECYZ-2000 Capacity: 1.2-1.5t/h

Preparations before making pelletized fertilizer— chicken manure compost productio

Generally speaking, the raw material for granulation should be composted chicken manure. Therefore, composting chicken manure is the first step to make chicken manure fertilizer pellets. The heat produced in composting will kill weed seeds, pathogens and other harmful materials in fresh chicken manure. Meanwhile, microorganism activity during composting will convert organic matters in chicken manure to nutrient materials. And above all, the structure of chicken manure will become loose and fine after composting, which is convenient for granulation. Finally, you can adopt SEEC compost turner to make quality chicken manure compost in a short time.

Several tips on chicken manure granulation system

As we mentioned, 3 types adapted wet granulation technology you can choose are suitable for making chicken manure pellets fertilizer. Although they are helpful for you to make pellets easily and quickly, there are several problems you should to pay more attention on.

- Proper water content in making pellets. Compared with dry granulation technology, those organic fertilizer granulator adapts advanced wet granulation technology, which need water content to form pellet for your needs. Therefore, adding some water in the process is very necessary. For its standard, 25%-30% water content is available. By this way, the shape of pellets can meet your needs. On the contrary, less or more than this standard of waste content is not good for making shape.

- Whether need add adhesive in the process. For some special materials, it is hard to form fertilizer pellets. In our company, we can provide new type organic fertilizer granulator to solve the problem. However, the price is very expensive among all granulator. Therefore, for others, by testing adding adhesive can meet your needs.

- Purchasing fertilizer equipment following salesman’s advice. How to choose high quality cow manure granulation machine in a short time is the noticeable point when you start to set up your business. Honestly speaking, salesman can offer your accurate details on our products, including discounts, application, operation rules, etc. In a word, a good salesman can cut down time for you. Or a series of difficulties will come.